Maintenance/Lubrication

Operation & Maintenance Manual

23221138 (5/08) Rev B

43

Belt Checking and Adjustment Procedure

Access for measuring or adjusting belt tension is via removal of the roof panel. Check belt

tension occasionally, especially if looseness is suspected.

A belt tension measurement device can be used to determine the tension of the belt.

To tension the belt, follow these steps:

1. Remove the roof panel.

2. Loosen the four (4) bolts that hold the motor bracket to the sub-base.

3. Turn the tension bolts clockwise to increase tension. Check tension with gage;

adjust until tension is within specification. Tension belts are accessed through

the unit end panel. The lock nuts must be loosened to allow adjustment.

Tighten lock nuts after adjustment.

4. Ensure pulleys are aligned. Rotate air pump slightly, if necessary.

5. Tighten bracket.

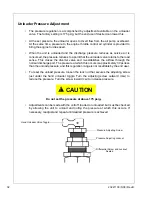

NOTE: Use tension gage in combination with straight edge placed at

bottom of pulley faces along side of the belt. At the center of the span,

perpendicular to the belt and midway of the free span, apply pressure to

the gage until the deflection shown in the table is read. Check the force

reading on the gage and compare to table. Reading must be within the

specification.

CAUTION

!

Improper pulley/sheave alignment and belt tension can result in motor

overload, excessive vibration, and premature belt and/or bearing failure.

To prevent these problems from occurring, ensure the pulley and sheave

are aligned and belt tension is satisfactory after installing new belt or

tensioning existing belts.

Application

Deflection, inches (mm)

MIN.Tension, lbs (kg)

MAX. Tension, lbs (kg)

New Belt

0.316 (8.0)

10.16 (4.6)

10.82 (4.9)

Checking Used Belt

0.316 (8.0)

8.86 (4.0)

9.50 (4.3)

Summary of Contents for Ingersoll Rand VHP40RMD

Page 2: ...2...

Page 5: ...23221138 5 08 Rev B 5 Safety...

Page 15: ...23221138 5 08 Rev B 15 Installation...

Page 23: ...23221138 5 08 Rev B 23 General Data...

Page 26: ...Operation Maintenance Manual General Data 26 23221138 5 08 Rev B...

Page 27: ...23221138 5 08 Rev B 27 Operating Instructions...

Page 35: ...23221138 5 08 Rev B 35 Maintenance Lubrication...

Page 44: ...44 23221138 5 08 Rev B...