Summary of Contents for P185WDOU-T4F (F89)

Page 2: ......

Page 3: ...iii...

Page 4: ......

Page 10: ...10...

Page 11: ...Foreword 11...

Page 14: ...14...

Page 15: ...Safety 15...

Page 37: ...Lifting Transporting and Preparation 37...

Page 46: ...46...

Page 47: ...Noise Emission 47...

Page 53: ...General Data 53...

Page 57: ...Operating Instructions 57...

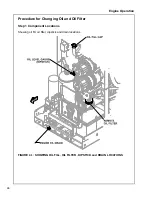

Page 77: ...Engine Operation 77...

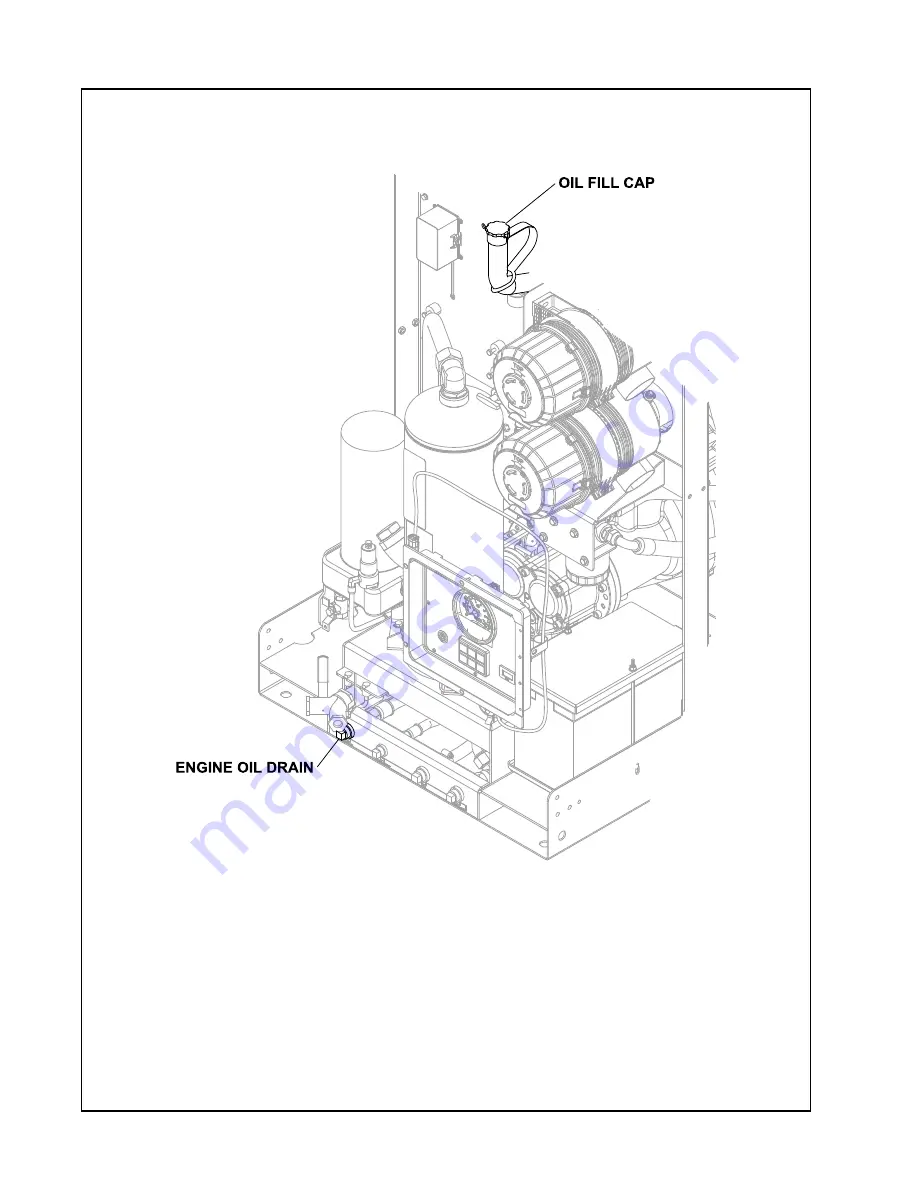

Page 115: ...Lubrication 115...

Page 120: ...120...

Page 121: ...Maintenance 121...

Page 141: ...Troubleshooting 141...

Page 150: ...150...

Page 151: ...Compressor Diagnostic Codes 151...

Page 156: ...156...

Page 157: ...Engine Fault Codes 157...

Page 158: ...Engine Fault Codes Engine Fault Code List 158...

Page 159: ...Engine Fault Codes Engine Fault Code List 159...

Page 160: ...Engine Fault Codes Engine Fault Code List 160...

Page 161: ...Engine Fault Codes Engine Fault Code List 161...

Page 162: ...Engine Fault Codes Engine Fault Code List 162...

Page 163: ...Engine Fault Codes Engine Fault Code List 163...

Page 164: ...Engine Fault Codes Engine Fault Code List 164...

Page 165: ...Engine Fault Codes Engine Fault Code List 165...

Page 166: ...Engine Fault Codes Engine Fault Code List 166...

Page 167: ...Engine Fault Codes Engine Fault Code List 167...

Page 168: ...Engine Fault Codes Engine Fault Code List 168...

Page 169: ...Preventive Maintenance Schedule PMS 169...

Page 171: ...Torque Values 171...

Page 175: ...Wiring Diagrams 175...

Page 176: ...Compressor and Engine Harness 176...

Page 177: ...177...

Page 178: ...178...

Page 179: ...179...

Page 180: ...180...

Page 181: ...Compressor and Engine Control System 181...

Page 182: ...182...

Page 183: ...183...

Page 184: ...P185WDOU Generator Option 184...

Page 185: ...185...

Page 186: ...Electrical Parts List 186...

Page 187: ...187...

Page 188: ...INTENTIONALLY LEFT BLANK 188...

Page 189: ...Warranty 189...

Page 190: ...Warranty Warranty Doosan Portable Power General Warranty Information 190...

Page 191: ...Warranty Truck Mounted Equipment 191...

Page 194: ......

Page 195: ......