General Maintenance Information

Any unauthorized modify cation or failure to maintain this equipment

may make it unsafe and out of factory warranty.

If performing more than visual inspections, disconnect Negative (-)

battery cable and open manual blowdown valve.

Use extreme care to avoid contacting hot surfaces (engine exhaust

manifold, piping, air receiver, and air discharge piping, etc.).

Never operate this machine with any guards removed.

Inch and metric hardware were used in the design and assembly of this

unit. Consult the parts manual for clarification of usage.

Disregard any maintenance pertaining to components not provided on

your machine.

This section refers to the various components which require periodic maintenance and

replacement.

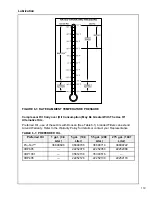

The Maintenance Schedule indicates the various components' descriptions and the intervals

when maintenance has to take place. Fluid capacities can be found in the General Data

of this manual. For any specification or specific requirement on service or preventative

maintenance for the engine, refer to the Engine Manual.

In addition to periodic inspections, many of the components in these units require

periodic servicing to provide maximum output and performance. Servicing may consist

of pre-operation and post-operation procedures to be performed by the operating or

maintenance personnel. The primary function of preventive maintenance is to prevent failure,

and consequently, the need for repair. Preventive maintenance is the easiest and the least

expensive type of maintenance. Maintaining your unit and keeping it clean at all times will

facilitate servicing.

Compressed air can be dangerous if incorrectly handled. Review all maintenance precautions

listed below before attempting any maintenance work on the compressor.

122

Summary of Contents for P185WDOU-T4F (F89)

Page 2: ......

Page 3: ...iii...

Page 4: ......

Page 10: ...10...

Page 11: ...Foreword 11...

Page 14: ...14...

Page 15: ...Safety 15...

Page 37: ...Lifting Transporting and Preparation 37...

Page 46: ...46...

Page 47: ...Noise Emission 47...

Page 53: ...General Data 53...

Page 57: ...Operating Instructions 57...

Page 77: ...Engine Operation 77...

Page 115: ...Lubrication 115...

Page 120: ...120...

Page 121: ...Maintenance 121...

Page 141: ...Troubleshooting 141...

Page 150: ...150...

Page 151: ...Compressor Diagnostic Codes 151...

Page 156: ...156...

Page 157: ...Engine Fault Codes 157...

Page 158: ...Engine Fault Codes Engine Fault Code List 158...

Page 159: ...Engine Fault Codes Engine Fault Code List 159...

Page 160: ...Engine Fault Codes Engine Fault Code List 160...

Page 161: ...Engine Fault Codes Engine Fault Code List 161...

Page 162: ...Engine Fault Codes Engine Fault Code List 162...

Page 163: ...Engine Fault Codes Engine Fault Code List 163...

Page 164: ...Engine Fault Codes Engine Fault Code List 164...

Page 165: ...Engine Fault Codes Engine Fault Code List 165...

Page 166: ...Engine Fault Codes Engine Fault Code List 166...

Page 167: ...Engine Fault Codes Engine Fault Code List 167...

Page 168: ...Engine Fault Codes Engine Fault Code List 168...

Page 169: ...Preventive Maintenance Schedule PMS 169...

Page 171: ...Torque Values 171...

Page 175: ...Wiring Diagrams 175...

Page 176: ...Compressor and Engine Harness 176...

Page 177: ...177...

Page 178: ...178...

Page 179: ...179...

Page 180: ...180...

Page 181: ...Compressor and Engine Control System 181...

Page 182: ...182...

Page 183: ...183...

Page 184: ...P185WDOU Generator Option 184...

Page 185: ...185...

Page 186: ...Electrical Parts List 186...

Page 187: ...187...

Page 188: ...INTENTIONALLY LEFT BLANK 188...

Page 189: ...Warranty 189...

Page 190: ...Warranty Warranty Doosan Portable Power General Warranty Information 190...

Page 191: ...Warranty Truck Mounted Equipment 191...

Page 194: ......

Page 195: ......