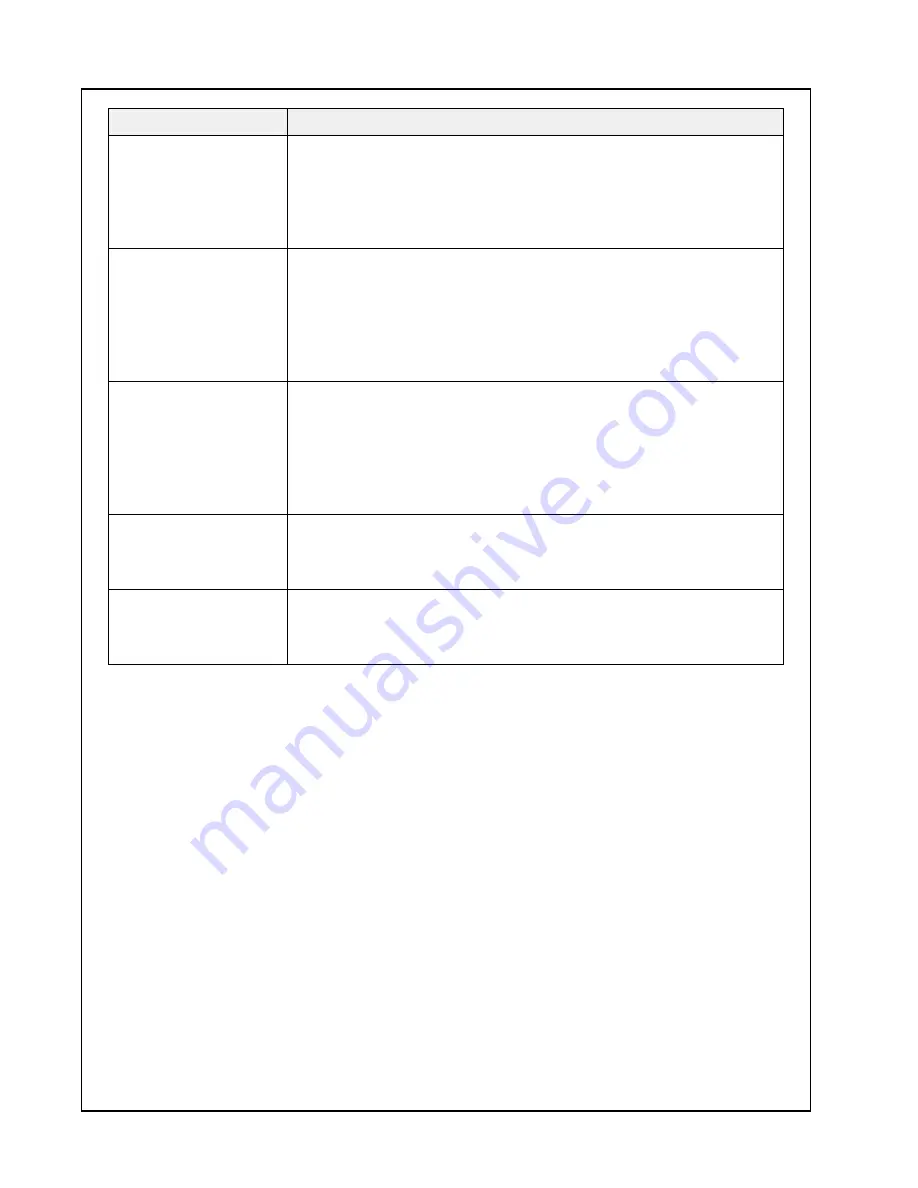

PERIOD

DESCRIPTION

100 HOURS

AIR INTAKE AND ENGINE EXHAUST

Engine and compressor air intake and engine exhaust systems

should be inspected after each 100 hours of operation for loose,

damaged, or deteriorated components. Repairs or replacements

should be made before the next period of use.

250 HOURS

COOLING SYSTEMS

All components of the cooling system for engine water and

compressor oil should be inspected every 250 hours of use.

Any discrepancies found should be corrected before placing the

compressor back in operation. Unrestricted airflow over the radiator

and oil cooler must be maintained at all times during operation.

250 HOURS

ISOLATION MOUNTS

Engine/Airend isolation mounts should be inspected after each

250 hours of operation. Those mounts with cracks or splits in the

molded rubber or with bent or broken bolts due to operation or

storage in severe environments should be replaced with equivalent

parts.

See Operator Manual

ENGINE OPERATION

Inspect and maintain engine condition and operation as

recommended in the manuals supplied by the engine manufacturer.

See Operator Manual

FUELS AND LUBRICANTS

Use only the types and grades of fuels and lubricants recommended

in the Operator and Maintenance Manual and Engine Manual.

50

Summary of Contents for P185WDOU-T4F (F89)

Page 2: ......

Page 3: ...iii...

Page 4: ......

Page 10: ...10...

Page 11: ...Foreword 11...

Page 14: ...14...

Page 15: ...Safety 15...

Page 37: ...Lifting Transporting and Preparation 37...

Page 46: ...46...

Page 47: ...Noise Emission 47...

Page 53: ...General Data 53...

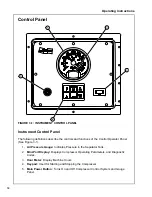

Page 57: ...Operating Instructions 57...

Page 77: ...Engine Operation 77...

Page 115: ...Lubrication 115...

Page 120: ...120...

Page 121: ...Maintenance 121...

Page 141: ...Troubleshooting 141...

Page 150: ...150...

Page 151: ...Compressor Diagnostic Codes 151...

Page 156: ...156...

Page 157: ...Engine Fault Codes 157...

Page 158: ...Engine Fault Codes Engine Fault Code List 158...

Page 159: ...Engine Fault Codes Engine Fault Code List 159...

Page 160: ...Engine Fault Codes Engine Fault Code List 160...

Page 161: ...Engine Fault Codes Engine Fault Code List 161...

Page 162: ...Engine Fault Codes Engine Fault Code List 162...

Page 163: ...Engine Fault Codes Engine Fault Code List 163...

Page 164: ...Engine Fault Codes Engine Fault Code List 164...

Page 165: ...Engine Fault Codes Engine Fault Code List 165...

Page 166: ...Engine Fault Codes Engine Fault Code List 166...

Page 167: ...Engine Fault Codes Engine Fault Code List 167...

Page 168: ...Engine Fault Codes Engine Fault Code List 168...

Page 169: ...Preventive Maintenance Schedule PMS 169...

Page 171: ...Torque Values 171...

Page 175: ...Wiring Diagrams 175...

Page 176: ...Compressor and Engine Harness 176...

Page 177: ...177...

Page 178: ...178...

Page 179: ...179...

Page 180: ...180...

Page 181: ...Compressor and Engine Control System 181...

Page 182: ...182...

Page 183: ...183...

Page 184: ...P185WDOU Generator Option 184...

Page 185: ...185...

Page 186: ...Electrical Parts List 186...

Page 187: ...187...

Page 188: ...INTENTIONALLY LEFT BLANK 188...

Page 189: ...Warranty 189...

Page 190: ...Warranty Warranty Doosan Portable Power General Warranty Information 190...

Page 191: ...Warranty Truck Mounted Equipment 191...

Page 194: ......

Page 195: ......