Operation in Winter

Preventing Coolant from Freezing

When only water used as coolant without mixing with antifreeze, corrosion in the engine,

degradation of cooling efficiency, and freezing of the engine in winter may occur. If the

engine is not operated for a long period during cold weather or in areas with cold climate,

fully discharge the coolant from the engine. Freezing of coolant leads to critical damage to

the engine. Please use a mixture of coolant with antifreeze at recommended ratio when

replacing or replenishing the coolant. The antifreeze prevents coolant from freezing.

Preventing Overcooling of the Engine

When the engine is cooled below the normal operating temperature, thermal efficiency

is lowered and fuel consumption as well as abrasion of the cylinder liner may increase.

Therefore, the engine should be operated within the normal operating temperature. If the

engine has been sufficiently operated, but the temperature of coolant remains below the

normal operating temperature, check the water temperature controller or other parts related

to the cooler.

Engine Oil

When viscosity of engine oil increases due to its low temperature during cold weather or in

areas with cold climate, the rpm may not be stable after starting the engine. To prevent this,

replace oil to engine oil for cold weather or areas with cold climate. When replacing engine

oil, use only genuine engine oil recommended by Doosan.

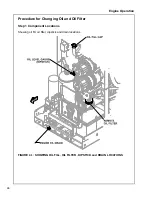

Cold Weather - The manual blowdown valve is closed for normal

operation. In extremely cold weather, fully opening the manual

blowdown valve prior to starting will allow the engine to crank faster and

start at a reduced load. Once the engine is running at idle speed, close

the manual blowdown valve slowly to ensure lubrication of the airend.

93

Summary of Contents for P185WDOU-T4F (F89)

Page 2: ......

Page 3: ...iii...

Page 4: ......

Page 10: ...10...

Page 11: ...Foreword 11...

Page 14: ...14...

Page 15: ...Safety 15...

Page 37: ...Lifting Transporting and Preparation 37...

Page 46: ...46...

Page 47: ...Noise Emission 47...

Page 53: ...General Data 53...

Page 57: ...Operating Instructions 57...

Page 77: ...Engine Operation 77...

Page 115: ...Lubrication 115...

Page 120: ...120...

Page 121: ...Maintenance 121...

Page 141: ...Troubleshooting 141...

Page 150: ...150...

Page 151: ...Compressor Diagnostic Codes 151...

Page 156: ...156...

Page 157: ...Engine Fault Codes 157...

Page 158: ...Engine Fault Codes Engine Fault Code List 158...

Page 159: ...Engine Fault Codes Engine Fault Code List 159...

Page 160: ...Engine Fault Codes Engine Fault Code List 160...

Page 161: ...Engine Fault Codes Engine Fault Code List 161...

Page 162: ...Engine Fault Codes Engine Fault Code List 162...

Page 163: ...Engine Fault Codes Engine Fault Code List 163...

Page 164: ...Engine Fault Codes Engine Fault Code List 164...

Page 165: ...Engine Fault Codes Engine Fault Code List 165...

Page 166: ...Engine Fault Codes Engine Fault Code List 166...

Page 167: ...Engine Fault Codes Engine Fault Code List 167...

Page 168: ...Engine Fault Codes Engine Fault Code List 168...

Page 169: ...Preventive Maintenance Schedule PMS 169...

Page 171: ...Torque Values 171...

Page 175: ...Wiring Diagrams 175...

Page 176: ...Compressor and Engine Harness 176...

Page 177: ...177...

Page 178: ...178...

Page 179: ...179...

Page 180: ...180...

Page 181: ...Compressor and Engine Control System 181...

Page 182: ...182...

Page 183: ...183...

Page 184: ...P185WDOU Generator Option 184...

Page 185: ...185...

Page 186: ...Electrical Parts List 186...

Page 187: ...187...

Page 188: ...INTENTIONALLY LEFT BLANK 188...

Page 189: ...Warranty 189...

Page 190: ...Warranty Warranty Doosan Portable Power General Warranty Information 190...

Page 191: ...Warranty Truck Mounted Equipment 191...

Page 194: ......

Page 195: ......