Operation & Maintenance Manual

Compressed Air

Compressed air can be dangerous if incorrectly handled. Prior to performing maintenance

or service on the compressor, ensure all pressure is vented from the system and the

compressor cannot be started accidentally.

Ensure the compressor is operating at the rated pressure and the rated pressure is known

to all relevant personnel.

All air pressure equipment installed in, or connected to, the compressor must have safe

working pressure ratings of at least the compressor safety valve setting.

If more than one compressor is connected to one common downstream plant, effective check

valves and isolation valves must be fitted and controlled by work procedures, to ensure one

compressor cannot accidentally be pressurized or over pressurized by another.

Compressed air must not be used for a direct feed to any form of breathing apparatus or

mask.

Compressed air can cause serious injury or death. Relieve pressure before removing filler

plugs/caps, fittings, or covers.

Air pressure can remain trapped in air supply line which can result in serious injury or death.

Always carefully vent air supply line at tool or vent valve before performing any service or

maintenance.

Discharged air contains a very small percentage of compressor lubricating oil and care

should be taken to ensure downstream equipment is compatible.

If discharged air is to be ultimately released into a confined space, adequate ventilation

must be provided.

When using compressed air, always use appropriate personal protective equipment.

All pressure containing parts, especially flexible hoses and their couplings, must be regularly

inspected, be free from defects, and be replaced according to the manual instructions.

Avoid bodily contact with compressed air.

The safety valve located in the separator tank must be checked periodically for correct

operation.

Whenever the compressor is stopped, air will flow back into the compressor from downstream

devices or systems unless the service valve is closed. Install a check valve at the compressor

service valve to prevent reverse flow in the event of an unexpected shutdown when the

service valve is open.

Disconnected air hoses whip and can cause serious injury or death. Always attach a safety

flow restriction to each hose at the source of supply or branch line in accordance with OSHA

Regulation 29 CFR Section 1926.302(b).

Never allow the compressor to sit stopped with pressure in the separator tank or piping.

15

Summary of Contents for P250/HP210WKUB-EX-T2

Page 2: ......

Page 3: ......

Page 6: ...Foreword 5 ...

Page 9: ...8 ...

Page 10: ...Drawbar Information 9 ...

Page 13: ...12 ...

Page 14: ...Safety 13 ...

Page 23: ...Operation Maintenance Manual Safety 22 ...

Page 24: ...Safety Operation Maintenance Manual 23 ...

Page 25: ...Operation Maintenance Manual Safety 24 ...

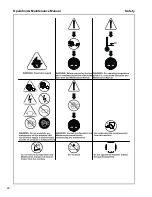

Page 26: ...Safety Operation Maintenance Manual Decal Symbols Graphic Form and Meaning of ISO Symbols 25 ...

Page 27: ...Operation Maintenance Manual Safety 26 ...

Page 28: ...Safety Operation Maintenance Manual 27 ...

Page 29: ...Operation Maintenance Manual Safety 28 ...

Page 30: ...General Data 29 ...

Page 33: ...32 ...

Page 34: ...Operating Instructions 33 ...

Page 43: ...42 ...

Page 44: ...Maintenance 43 ...

Page 53: ...Operation Maintenance Manual Maintenance Maintenance Schedule 52 ...

Page 54: ...Lubrication 53 ...

Page 58: ...Troubleshooting 57 ...

Page 64: ...WARRANTY 63 ...

Page 65: ...64 ...

Page 66: ...65 ...

Page 67: ...66 ...

Page 69: ......

Page 70: ......