Operation & Maintenance Manual

Some of the air lines are nylon tubing. The associated fittings are

“push-in” design. Features are as follows:

Pulling on the tubing will cause the inner sleeve to withdraw and compress, thus tightening

the connection. The tubing can be withdrawn only while holding the sleeve against the fitting.

The tubing can be removed and replaced numerous times without losing its sealing ability.

To install the nylon tubing, make a mark (with tape or grease pencil) approximately 7/8

inch from the end of the tubing. Insert the tubing into the sleeve and “push-in” past the first

resistance to the bottom. The mark should be approximately 1/16 inch from the sleeve, for

the 3/8 inch O.D. tubing; 1/8 inch for the 0.25 inch O.D. tubing. This will ensure that tubing

is fully engaged in the sealing mechanism.

47

Summary of Contents for P250/HP210WKUB-EX-T2

Page 2: ......

Page 3: ......

Page 6: ...Foreword 5 ...

Page 9: ...8 ...

Page 10: ...Drawbar Information 9 ...

Page 13: ...12 ...

Page 14: ...Safety 13 ...

Page 23: ...Operation Maintenance Manual Safety 22 ...

Page 24: ...Safety Operation Maintenance Manual 23 ...

Page 25: ...Operation Maintenance Manual Safety 24 ...

Page 26: ...Safety Operation Maintenance Manual Decal Symbols Graphic Form and Meaning of ISO Symbols 25 ...

Page 27: ...Operation Maintenance Manual Safety 26 ...

Page 28: ...Safety Operation Maintenance Manual 27 ...

Page 29: ...Operation Maintenance Manual Safety 28 ...

Page 30: ...General Data 29 ...

Page 33: ...32 ...

Page 34: ...Operating Instructions 33 ...

Page 43: ...42 ...

Page 44: ...Maintenance 43 ...

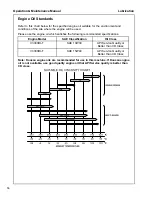

Page 53: ...Operation Maintenance Manual Maintenance Maintenance Schedule 52 ...

Page 54: ...Lubrication 53 ...

Page 58: ...Troubleshooting 57 ...

Page 64: ...WARRANTY 63 ...

Page 65: ...64 ...

Page 66: ...65 ...

Page 67: ...66 ...

Page 69: ......

Page 70: ......