AUTOMATIC SHUTDOWN/DIAGNOSTICS

Should any of these problem situations occur, the

unit will automatically shutdown and stop. BEFORE

restarting the unit or flipping the POWER switch to

“Off”, check the DIAGNOSTICS area on the

instrument panel.

The upper four (4) lamps are electronically “latched”

to only respond to the first or primary signal for a

shutdown. In other words, if the automatic shutdown

is the result of one of these four problems, only that

particular problem lamp will be lit. And the lamp will

remain lit as long as the batteries provide power.

Refer

to

OPERATING

CONTROLS

AND

INSTRUMENTS for the various problem signal

criteria (

°

F, psi, etc.). The indicated problem area

should be inspected for a physical cause (low fluid,

broken fan belt, evidence of excessive heat, etc.)

and corrections made.

Sensors (1) through (3), Switches (4) and (5) and

additional low oil pressure switch (mentioned above)

will automatically reset when the problem condition

is corrected.

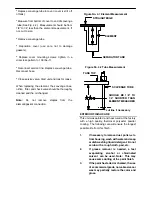

SPEED AND PRESSURE REGULATION

L

N

M

PR

H

AC

J

P

GC C

K

E

F

B D

BV

A

G

ADJUSTMENT INSTRUCTIONS

The operating pressure of this unit was set at the

factory to the maximum rating (at full speed). See

General Data. However, this pressure may be reset

down to 150 psi (1050 kPa).

Normally, regulation requires no adjusting; but if

proper adjustment is lost, proceed as follows:

Before Starting Unit --

1.

WITH UNIT STOPPED

, disconnect rod end

bearing on governor cable (GC) at engine

governor lever.

2.

At bracket (A) near butterfly valve (BV) run

nut (B) back on governor cable housing.

Push governor cable housing toward lever

(C). Tighten nut (D).

3.

Loosen screw (J) on lever (C).

4.

Loosen nut (E) to relax spring (G)

5.

Loosen nut (H). Turn rod (L) in Air Cylinder

(AC) until approximately 3/4 inch (20 mm)

between nut (H) and flats on rod (L).

6.

With locking pliers, clamp onto butterfly

valve shaft and rotate and hold it so butterfly

valve is fully shut. Place a wrench on lever

screw (K) and rotate butterfly valve lever (C)

so air cylinder rod (L) fully bottoms out in air

cylinder. While holding the butterfly valve

closed AND holding air cylinder shaft fully in,

tighten lever screw (J). Then release hold

on butterfly valve shaft and lever.

7.

Turn rod (L) One and one--half rounds out of

rod end bearing. Tighten nut (H). Rotate

butterfly shaft/lever (C), open and close,

several times to assure that linkage is not

binding.

8.

With engine governor lever in full speed

position, reconnect rod end bearing.

9.

Take slack out of spring (G) by moving nuts

(E) and (F). Tighten nuts.

Adjust spring so it is full stretched, and nut (F) is at

far end of rod, closest to spring (G). Tighten nuts.

10.

Start unit and allow to warm up for 3 to 5

minutes.

11.

Push “Service Air” button on control panel.

12.

With service air valve closed, adjust

pressure regulator (PR) to rated pressure

(*) plus 30 psi (70 kPa) as follows: