SECTION

5

-

MAINTENANCE

GENERAL

In addition to periodic inspections, many of the

components in these units require periodic servicing

to provide maximum output and performance.

Servicing may consist of pre--operation and

post--operation procedures to be performed by the

operating or maintenance personnel. The primary

function of preventive maintenance is to prevent

failure, and consequently, the need for repair.

Preventive maintenance is the easiest and the least

expensive type of maintenance. Maintaining your

unit and keeping it clean at all times will facilitate

servicing.

Correct engine speed is critical to the operation of

this machine. Check the idle and full load rpm every

three months and adjust in accordance with the

speed and pressure adjustment instructions in this

manual and included on a decal on the machine.

Correct speeds are on the general data decal.

SCHEDULED MAINTENANCE

The maintenance schedule is based on normal

operation of the unit. This page can be reproduced

and used as a checklist by the service personnel. In

the event unusual environmental operating

conditions exist, the schedule should be adjusted

accordingly.

COMPRESSOR OIL LEVEL

The oil level is most consistent when the unit is

RUNNING AT FULL LOAD and should be checked

at this time. The optimum operating level is midway

of the sight tube on the side of the receiver tank. See

the decal beside the sight tube. If the oil level is not

in the “OK” range, make appropriate corrections

(Add or Drain). A totally filled sight tube in which the

level is not visible indicates an over--full condition

and requires that oil be drained.

COMPRESSOR OIL

This machine was factory filled with ProTec

R

Compressor Fluid (XHP505 for XHP900 models).

By continued use of Portable Power compressor

fluids and filters, optional warranty will be extended

for the base airend (rotors, housings, gears and

bearings) when substantiated with proof of

conformance

to

recommended

maintenance

intervals and purchase of OEM Portable Power

filters and fluids.

Optional Warranty --

The earlier of 60 months from

shipment to, or the accumulation of 10,000 hours of

service by the initial user. The optional warranty is

limited to defects in major components (rotors,

housings and bearings), and is automatically

available to the original user when he meets the

following three conditions:

1. Submissions of proof that Doosan Portable Power

fluid, filters and separators have been used. Refer to

the Operation and Parts manual for the correct

fluids, filters and separator elements required.

2. Submission of proof that maintenance intervals

have been followed.

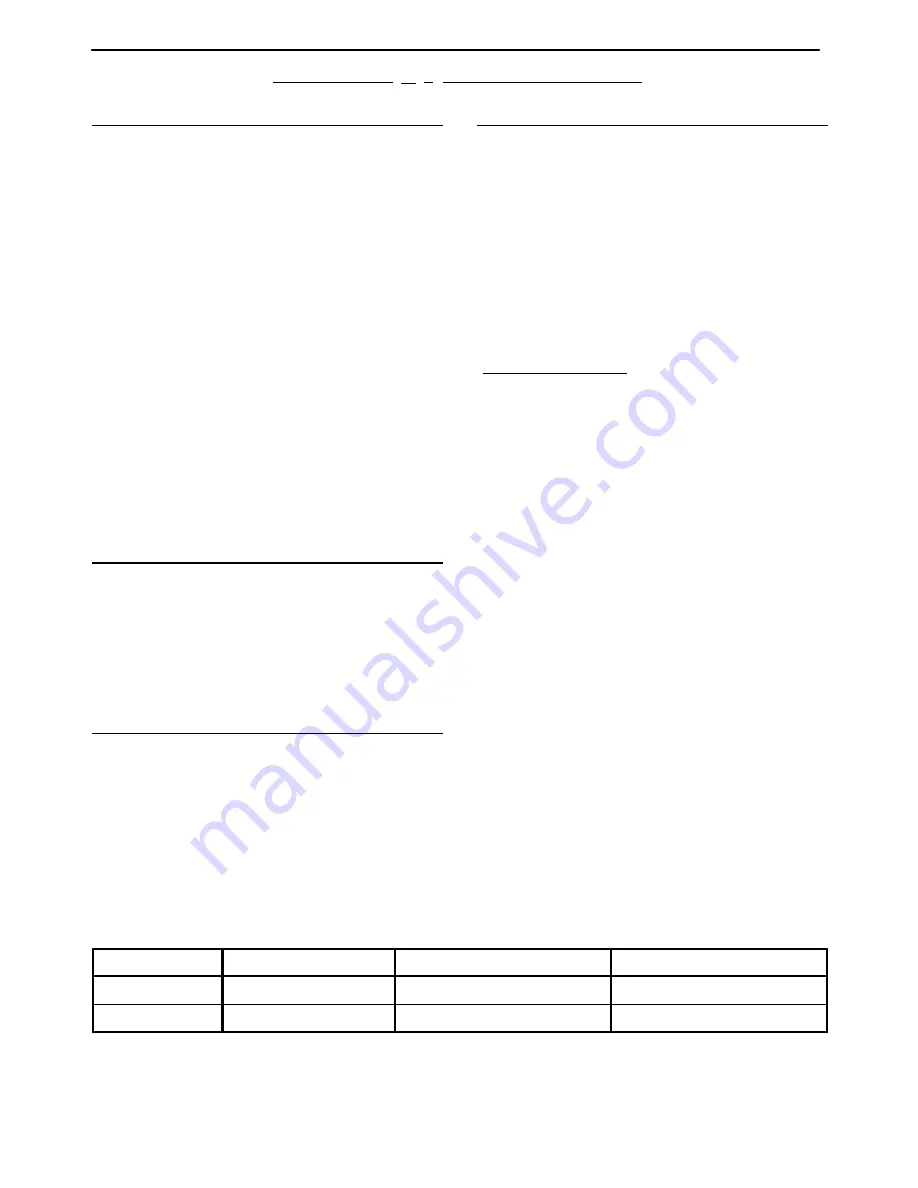

WARRANTY

TIME

*BARE AIREND

**AIREND COMPONENTS

STANDARD

2 yrs/4000 hrs

100% parts and labor

100% parts and labor

OPTIONAL

5 yrs/10,000 hrs

100% parts and labor

0%