The flexible hoses used in the fuel, oil and air lines

on these units are primarily used for their ability to

accommodate

relative

movement

between

components. It is extremely important they be

periodically inspected for wear and deterioration.

Clamps are used to prevent hose cover abrasion

through vibration. This abrasion may occur when

two hose lines cross, or when a hose line rubs

against a fixed point; therefore, it is necessary that

all clamps be replaced if missing. It is also important

the operator does not use the hoses as convenient

hand hold or steps. Such use can cause early cover

wear and hose failure.

NOTICE

Piping systems operating at less than 150 psi

(1050 kPa) may use a special nylon tubing. The

associated fittings are also of a special

“push--in” design. If so, features are as follows:

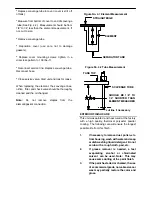

Pulling on the tubing will cause the inner sleeve to

withdraw and compress, thus tightening the

connection. The tubing can be withdrawn only while

holding the sleeve against the fitting. The tubing can

be removed and replaced numerous times without

losing its sealing ability.

To install the nylon tubing, make a mark (with tape or

grease pencil) approximately 7/8 inch from the end

of the tubing. Insert the tubing into the sleeve and

“push--in” past the first resistance to the bottom. The

mark should be approximately 1/16 inch from the

sleeve, for the 3/8 inch O.D. tubing; 1/8 inch for the

0.25 inch O.D. tubing. This will ensure that the

tubing is fully engaged in the sealing mechanism.

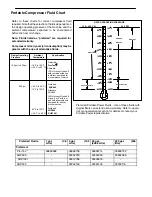

COMPRESSOR OIL FILTERS

The compressor lubrication and cooling oil system

includes dual spin--on, throw away type oil filters,

each with an internal bypass valve. With a clean,

new filter element, all of the oil flows through the full

element area, from the outside/inside. As each

element becomes contaminated with dirt, a pressure

differential is created in the filter housing between

the oil inlet and outlet ports. As this differential

approaches 25 psi (175 kPa), the bypass valve

starts to open, thus permitting a small quantity of oil

to bypass the filter. As the contaminants continue to

build up, more and more of the oil bypasses the filter

media itself.

This bypass does not provide any filtration but does

allow a maximum flow of compressor lubricating and

cooling oil to preclude any possible damage from

loss of oil. Also the design of the filter prevents any

washing--off of any dirt during oil bypassing.

NOTICE

The oil filter must be replaced every 500 hours of

operation. On new or overhauled units, replace

the element after the first 50 and 150 hours of

operation; thereafter, service the oil filter every

500 hours.

To service the oil filters it will first be necessary to

shut the unit down. Wipe off any external dirt and oil

from the exterior of the filter to minimize any

contamination from entering the lubrication system.

Proceed as follows:

WARNING

High pressure air can cause severe injury or

death from hot oil and flying parts. Always

relieve pressure before removing caps, plugs,

covers or other parts from pressurized air

system.

1. Open the service air valve(s) to ensure that

system is relieved of all pressure. Close the valve(s).

2. Turn

the

spin--on

filter

element

counterclockwise to remove it from the filter housing.

Inspect the filter element and then discard.