dormakaba 8600 EMR Installation Instructions

08281010

03-2020

8600 EMR

4

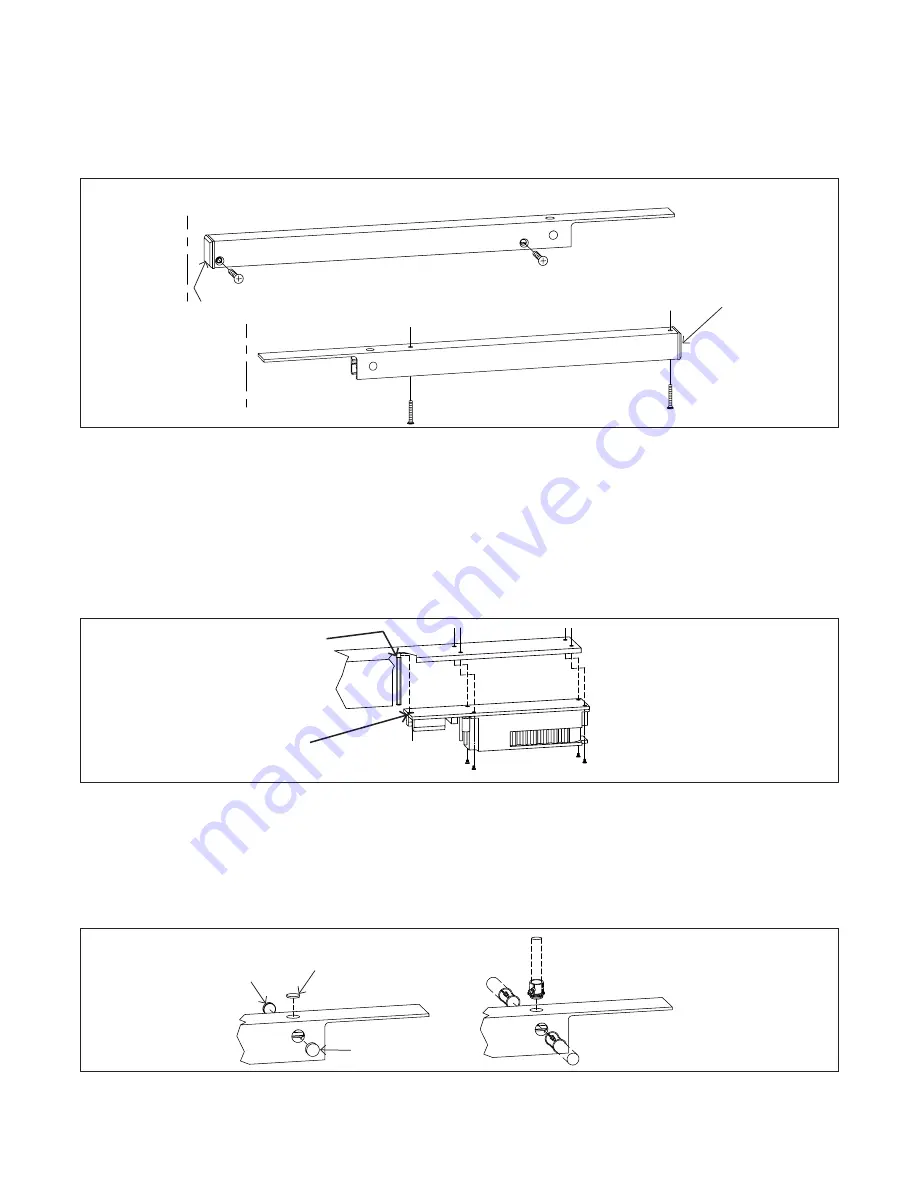

Track

Detector

Slide channel

2.1 Installing track to frame

2

Installation instructions

2.2.1

Slide detector slot under standoff and attach

with four screws.

NOTE: If construction is still being completed near

detector installation “DO NOT” install detector at this

time, or protect the detector from construction dust

contaminants.

2.2 Install detector

Fig.2

Fig.1

2.1.1

8600T and 8600DE:

•

Install with detector cut-out toward latch edge

of door.

•

Use two 1/4-20x2” metal or two No. 14x2-3/4”

wood screws.

8600T and 8600DE

Standoff

8600PT

Hinge

Hinge

CL

CL

2.1.2

8600PT:

•

Install with detector cut-out toward latch edge

of door.

•

Use two 1/4-20x2” metal or two No. 14x2-3/4”

wood screws.

End cap

End cap

Slot

2.3 Installing the slide channel

Fig.3

2.3.1

Remove one wire access plug according to the

installation type.

NOTE: Three access wire holes on optional surface

wired units only.

T & DE (RH)

T & DE (LH)

(Surface conduit)

NOTE: No top plug on

PT mounts