34

Crane 4000LE

07-2022

RL6002-001

Crane 4000LE Installation Manual

In-ground Motion Assist 360 drive and speed control

Remote control enclosure

Chapter 9

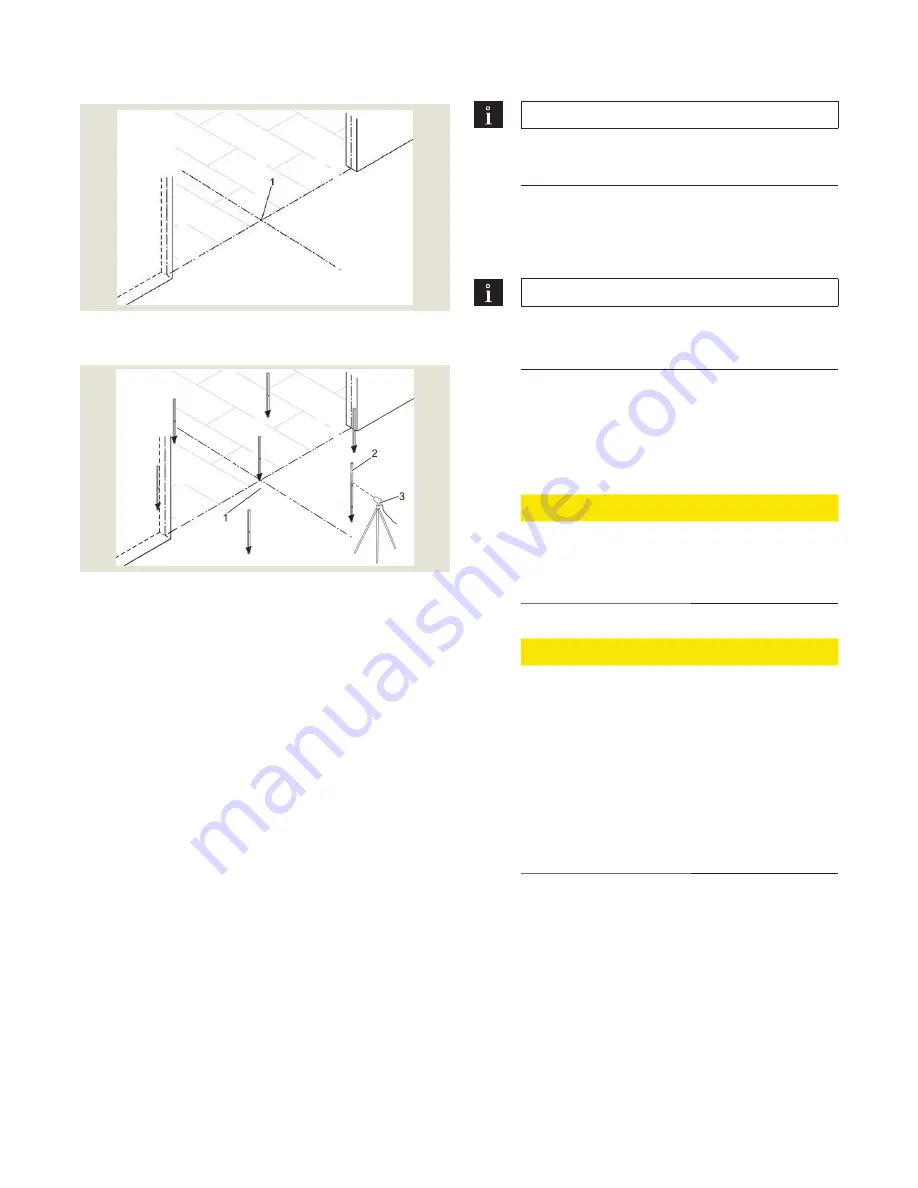

Fig. 9.2.1 Center of revolving door axis

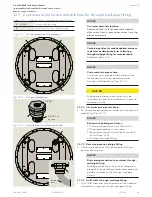

Fig. 9.2.2 Laser level measuring points

3

Laser leveling device

9.2.2 Check level of finished floor.

TIPS AND RECOMMENDATIONS

Check floor level procedure in Para. 9.2.2 is a

recommendation.

1. Position leveling device horizontally in front of

assembly surface (Fig. 9.2.2).

2. Position leveling staff vertically at any point on

assembly floor surface to select a reference point.

TIPS AND RECOMMENDATIONS

The reference point (step 2) is used for the

following measurements.

3. Measure reference point and note reading.

4. Take measurements at a minimum of 6 different

points, as shown in Fig. 10.4.2 and note readings.

5. Compare measurement points with reference value.

The deviation tolerance is 1/16" [2 mm].

CAUTION

If measurements are outside of the deviation

tolerance, the finished floor must be reworked

or re-prepared by the building contractor.

9.2.3 Mark center of revolving door axis.

CAUTION

Material damage due to incorrect marking of

revolving door axis center!

Inaccurate marking of the center of the axis of

the revolving door on the assembly surface can

lead to subsequent discrepancies during

assembly. This can result in faults and material

damage.

• Always accurately mark the axis center.

• Always use the supplied drilling template to

mark hole locations.

1. Go to Chapter 10, Floor template.

1

Axis

center

1

Axis

center

2

Leveling

staff