42

Crane 4000LE

07-2022

RL6002-001

Crane 4000LE Installation Manual

In-ground Motion Assist 360 drive and speed control

Remote control enclosure

Chapter 12

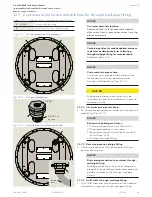

12.3 Install leveling plate in pit

12.3.1 Install set screws in leveling plate.

1. Install four set screws RF6028 in leveling plate.

• Install set screws to an equal depth of 5/8" below

leveling plate (Fig. 12.3.4).

Fig. 12.3.1 Leveling plate RC6022

1

(4)

2

Fig. 12.3.2 Leveling plate with set screws installed

2

Fig. 12.3.3 Set screw RF6028-01G

1

(4)

2

2

5/8”

Fig. 12.3.4 Set screw depth

1

RC6022

Leveling plate

2

RF6028-01G

1/2-13 x 2" cup point set screw

Table 12.3.1

Leveling plate and hardware