54

ED50

08-2018

DL4614-140

dormakaba ED50 OHC Installation Instructions

Chapter 26

26.1 Customer 115 Vac connection

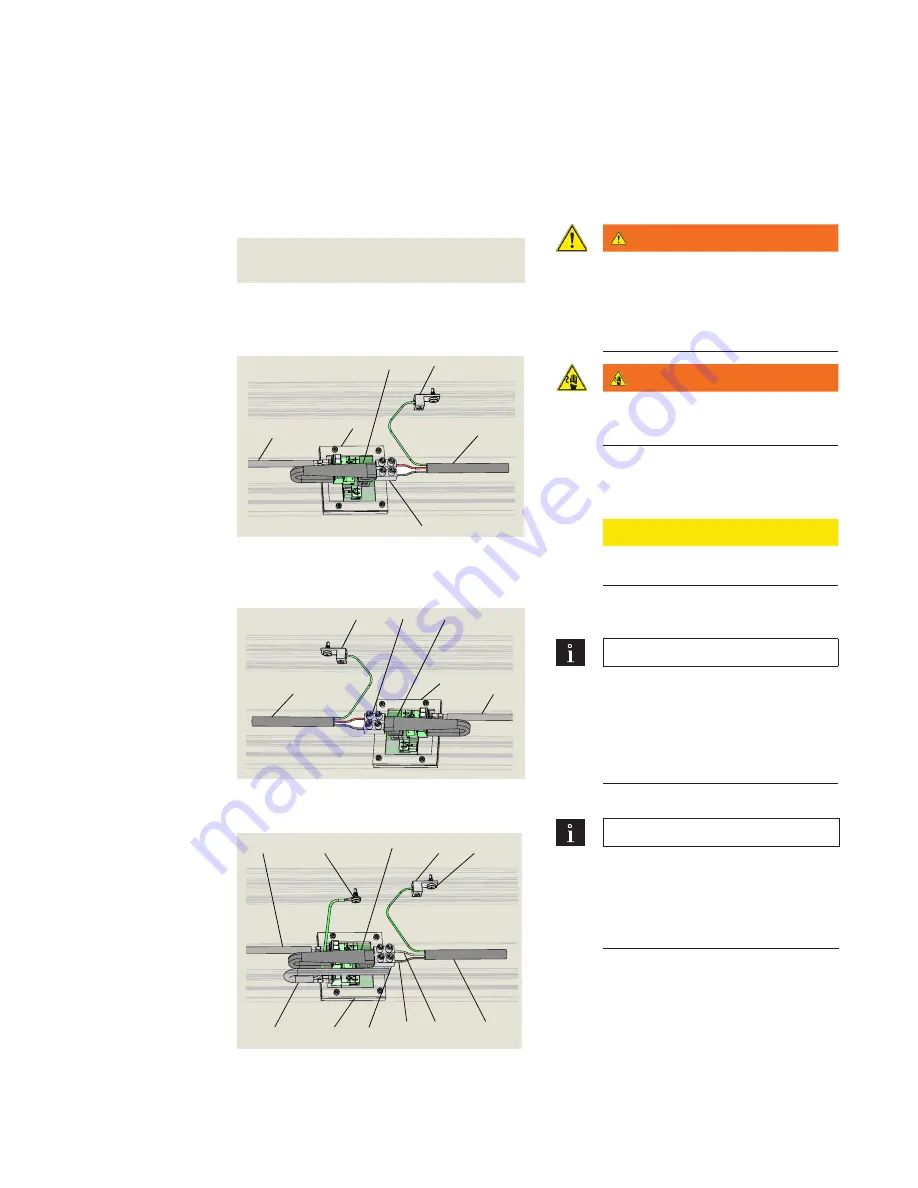

Fig. 26.1.4 Customer 115 Vac connection,

double door header

26 Customer 115 Vac connection

26.1.1 Connect 115 VAC wiring.

WARNING

Routing and connection of 115 VAC

wiring to ED50 OHC operator

must be performed by a qualified

person!

WARNING

115 VAC branch circuit disconnect

or circuit breaker must be OFF!

1. Route wiring into header, use

appropriate fittings to secure wiring, and

route wiring to 115 VAC terminal block.

CAUTION

Use copper conductors only!

2. Terminate 115 VAC wiring at power

cable terminal block.

TIPS AND RECOMMENDATIONS

• Maximum wire strip length, 1/4".

• Tighten terminal screws to

torque referenced in Fig. 26.1.1.

• Leave service loop in wiring at

terminal block for maintenance.

3. Terminate ground wire at ground lug.

TIPS AND RECOMMENDATIONS

Install label in header with

panelboard and circuit breaker

number supplying 115 Vac to

header.

TIGHTEN MAINS TERMINAL TO 5-7 in-lb

Use Copper Conductors ONLY

Fig. 26.1.1 115 Vac terminal torque and wire

label

4

115 Vac power

extension cable

DX4647

5

115 Vac power module

5.1

Main power cable

DK3772-010

5.2

115 Vac terminal block

6

Ground lug kit

DK4656-010

6.1

Self tapping screw

7

115 Vac power cable

DX3484-030

10

Customer 115 Vac

5

5.1

10

6.1

6.1

6

115

Vac

N

7

4

5.2

Fig. 26.1.2 115 Vac connection; ED50

operator left side of header

4

115 Vac power

extension cable

DX4647

5

115 Vac power module

5.1

Main power cable

DK3772-010

5.2

115 Vac terminal block

6

Ground lug kit

DK4656-010

10

Customer 115 Vac

10

6

4

5

5.1

5.2

Fig. 26.1.3 115 Vac connection; ED50

operator right side of header

6

5.1

10

4

5

5.2

4

115 Vac power

extension cable

DX4647

5

115 Vac power module

5.1

Main power cable

DK3772-010

5.2

115 Vac terminal block

6

Ground lug kit

DK4656-010

10

Customer 115 Vac