43

ED900

02-2020

08125330

dormakaba ED900 Installation Instructions – Double egress door

Chapter 14

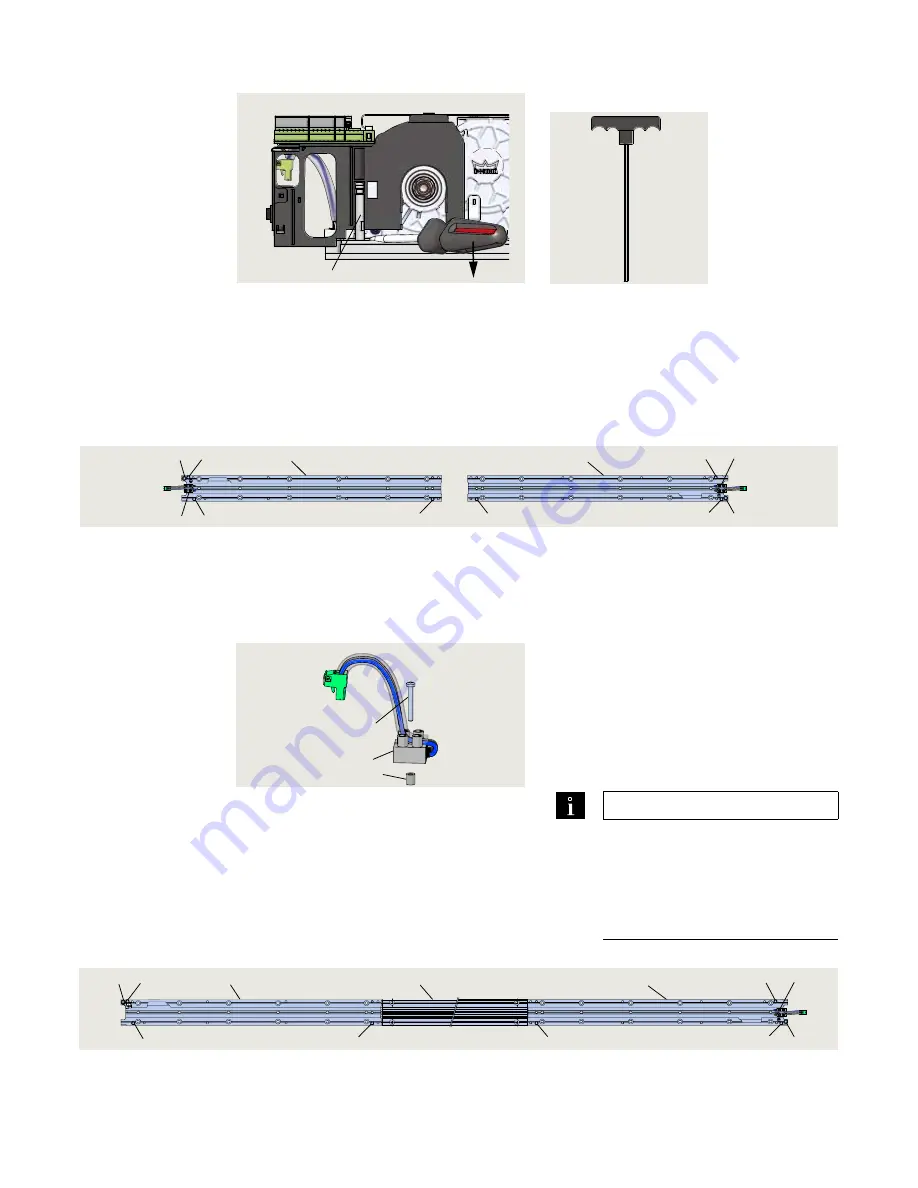

Fig. 14.1.3 Mounting plate removal

Fig. 14.1.4 5 mm T-handle

hex key

4

Guide pin

4

14.2 Mounting plate 115 Vac terminal blocks

1

M3 x 5 screw

2

115 Vac terminal

block

3

Spacer

Fig. 14.2.2 115 Vac terminal block assembly

1

2

3

14.2.1 ED900 installation with standard

covers

(Fig. 14.2.1)

1. Customer 115 Vac is connected to

terminal block and ground stud on each

ED900 mounting plate.

Fig. 14.2.1 ED900 mounting plates – installation with standard covers

1

3

2

3

4

4

5

5

5

5

5

5

1

Inactive door

mounting plate

2

Active door

mounting plate

14.2.2 ED900 installation with full width

cover option

(Fig. 14.2.2)

1. Customer 115 Vac is connected to

inactive door terminal block and ground

stud.

14.2.2 Remove 115 Vac terminal block on

inactive door mounting plate.

1. Remove M3 x 5 screw securing 115 Vac

terminal block assembly to mounting

plate.

2.

Remove 115 Vac terminal block assembly.

TIPS AND RECOMMENDATIONS

Removing 115 Vac terminal block

on inactive door mounting plate is

optional.

• Wiring between mounting

plates is facilitated by

removing terminal block.

Fig. 14.2.3 ED900 mounting plates – installation with optional full width cover example

1

Inactive door

mounting plate

2

Active door

mounting plate

1

2

3

4

4

5

5

5

5

5

5

6

3

115 VAC terminal

block

4

Ground terminal

3

115 VAC terminal

block

4

Ground terminal

5

Guide pin

5

Guide pin

6

Mounting plate

extension