Page 9

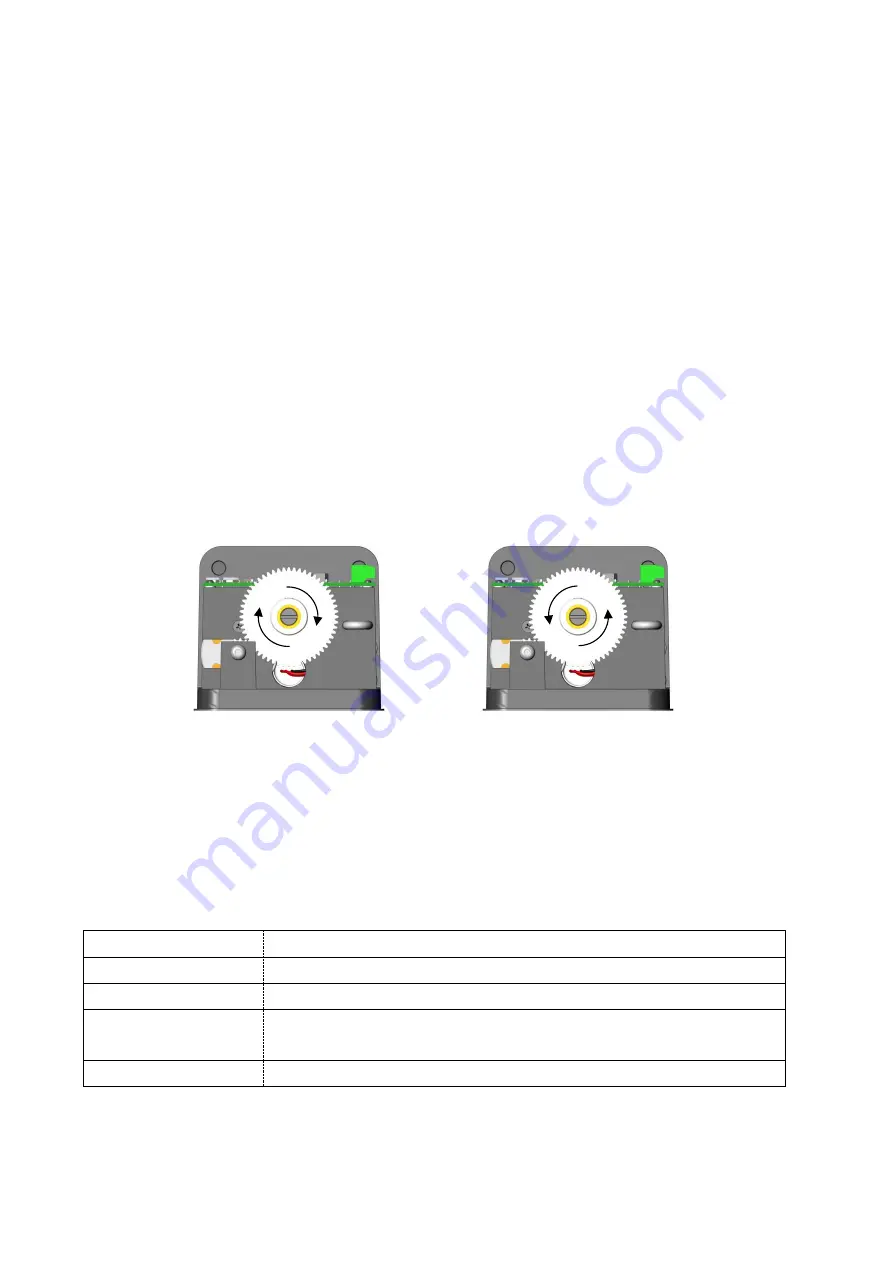

Clockwise turning of the large

gear will retract the bolt pin.

Anti-clockwise turning of the large

gear will extend the bolt pin.

The RD10 features multiple locking / unlocking to allow for misaligned doors or unforeseen problems. If the bolt pin

meets an obstruction as it is trying to secure the door, it stops and withdraws before attempting to lock again. It has

a total of three attempts to secure the door after which time it will sound an alarm. The same function is present when

the RD10 unlocks.

7.3 General

If the batteries are fitted and the power is removed to the RD10 at any time during its operation, the lock will revert

to its pre-selected state of either unlocked or locked. The RD10 has been designed to operate with

high quality

disposable alkaline batteries

and may not work correctly with alternatives. Should the batteries become flat the

lock will sound an alarm to indicate a battery change is required.

If the batteries are not replaced once they have become depleted, the RD10 will automatically revert to the Fail

Maintained state; i.e. in the event of a power failure the lock will stay in the position it was in before the power was

removed.

The three monitors can be used to provide door and bolt position information regardless of the locks configuration.

Manual operation of the RD10 is available by removing the cover to allow access to the lock mechanism. The supplied

key can be used to open and remove the cover and once access is available a screwdriver can be inserted into the

centre of the large gear and turned to move the bolt pin in or out.

7.4 Alarms

To offer instant feedback about the locks state, the RD10 has an on board beeper which sounds at various times.

The table below details the different alarms expected from the RD10.

Locked confirm

1 Short beep

Unlocked confirm

2 Short beeps

Failure to lock / unlock

5 Long beeps

Battery replacement

5 Short beeps sounded 5 seconds after a lock activation and repeated every

10 minutes until the batteries are replaced

Diagnostic

Various beeps

– used for service