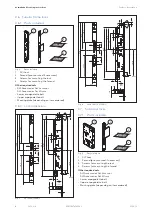

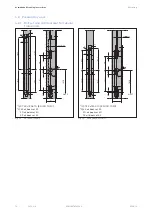

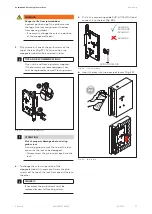

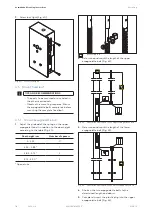

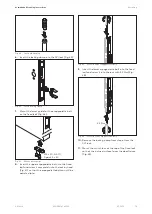

4.3 Preparatory work

4.3.1 Mill-cut and drill door leaf for tubular

frame locks

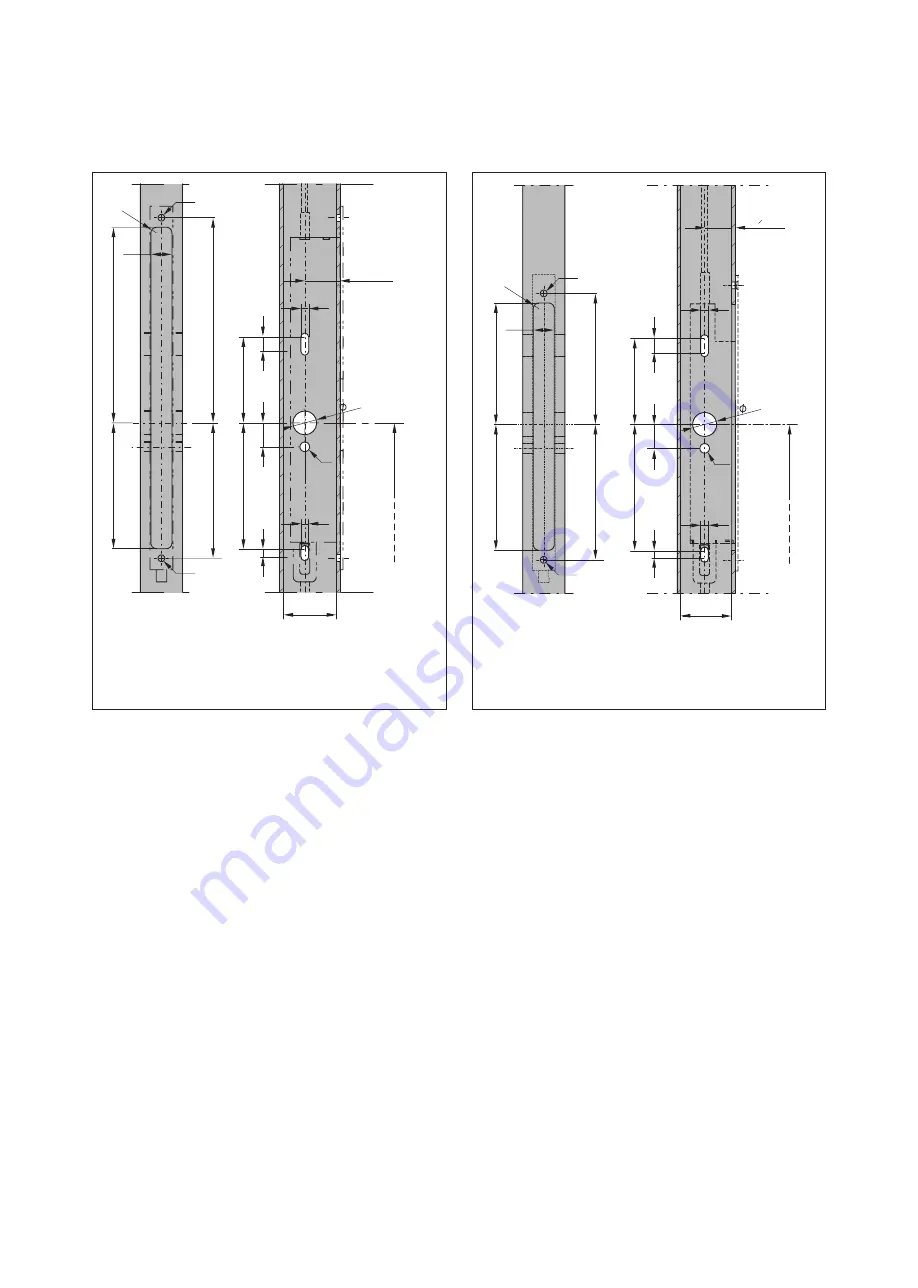

Fig. 19

25

22

R6

131,5

20

4

,5

214

,5

14

1,5

*1)

OKFF

1050

*1)

ø10

10

10

*2)

2

5

1,

32/37 42

/

15

90

131

7

,5

*1) ST 3.9x19 A2-70 (EN ISO 7050)

*2) 45 at backset 35

50 at backset 40

55 at backset 45

SVI 2000/2000F

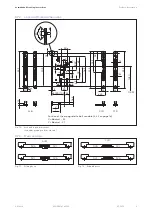

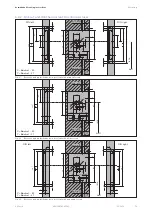

Fig. 20

25

2

5

1,

22

R6

131,5

133,5

14

4

,5

14

1,5

*1)

ø10

15

90

131

7

,5

10

10

*2)

*1)

32/37 42

/

OKFF

1050

*1) ST 3.9x19 A2-70 (EN ISO 7050)

*2) 45 at backset 35

50 at backset 40

55 at backset 45

SVI 4000/SVI 5000

12

SVI Lock

2019-12

dormakaba Mounting instructions

Mounting

WN 059741 45532