851-738 Rev. A

15

Dorner Mfg. Corp.

Brushless DC Motor Control

Operation

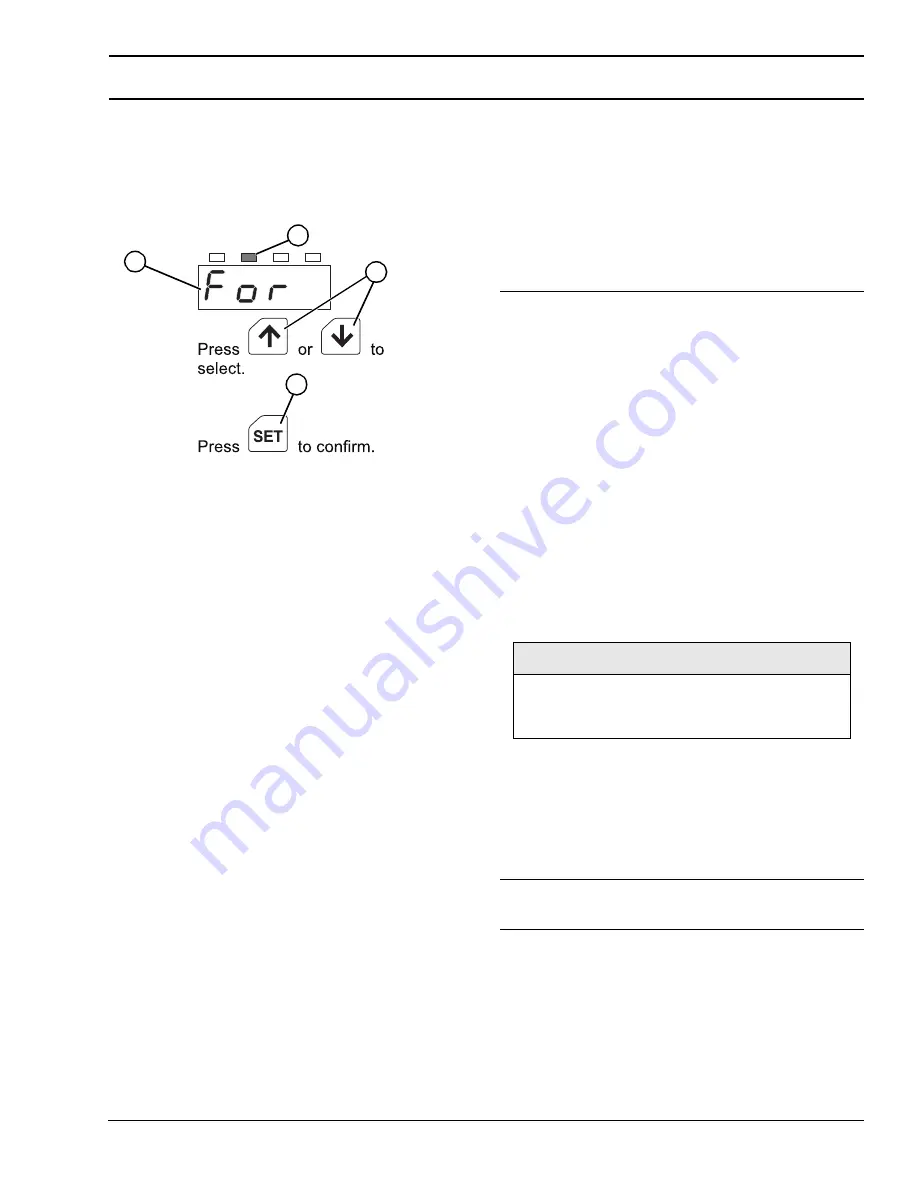

Set Motor Direction

The initial setting is “For” (clockwise).

1.

Press MODE to switch to the direction setting mode.

The F/R LED

will illuminate.

Figure 33

Figure 33

2.

Press up or down

to select a desired

direction. “For”

: Clockwise or

“rEv”: Counterclockwise.

3.

Press SET

to confirm the selection.

The display will blink.

Displaying the Conveyor Belt Speed

While the motor is operating, the speed of the motor output

shaft is displayed on the digital operator. To show the speed

of the conveyor belt (speed ft/minute), set the gear ratio to

the conveyor gear ratio in use.

1.

Calculate the conveyor gear ratio using the formula

below:

• Conveyor gear ratio =

• where:

• Gearhead ratio = ratio of inline or 90 degree gearbox

• Pulley diameter = Diameter of Drive Pulley (Ft)

- 2200 Series = 0.104

- 3200 Series = 0.25

- 2200 Precision Move End Drive Series = 0.125

- 2200 Precision Move Mid Drive Series = 0.167

- 3200 Precision Move End Drive Series = 0.275

- 2200 Modular Belt Series = 0.125

- 5300 Modular Belt Series = 0.325

- 5200 Modular Belt Series = 0.325

• Drive Sprocket Teeth = Number of teeth on sprocket

connected to gearmotor. Note: For all side drives = 1.

• Driven Sprocket Teeth = Number of teeth on sprocket

connected to conveyor shaft. Note: For all side drives = 1.

• Example:

- 2200 Series Conveyor with a 62M015PLBDDEN Gear-

motor and a light load bottom mount with a 44 tooth

pulley on the gearmotor and a 22 tooth pulley on the

conveyor.

• Conveyor gear ratio =

• Conveyor gear ratio = 21.5

F/R

4

1

3

2

(Gearhead Ratio) x (Drive Sprocket Teeth)

(4.28 Factor) x (Pulley Dia.) x (3.14) x (Driven Sprocket Teeth)

NOTE

To convert the display to meters/min., enter all

pulley diameters in meters and omit the 4.28

division factor in the equation.

(Gearhead Ratio) x (Drive Sprocket Teeth)

(4.28 Factor) x (Pulley Dia.) x (3.14) x (Driven Sprocket Teeth)

(15) x (44)

(4.28) x (0.104) x (3.14) x (22)