Page

|

1

REV#0002A

TJ1107XEDR

READ THOROUGHLY BEFORE INSTALLING

REV#0001A

IMPORTANT: Handle electro-magnets and armatures carefully. Any damage to the mating surfaces may significantly

reduce holding efficiency.

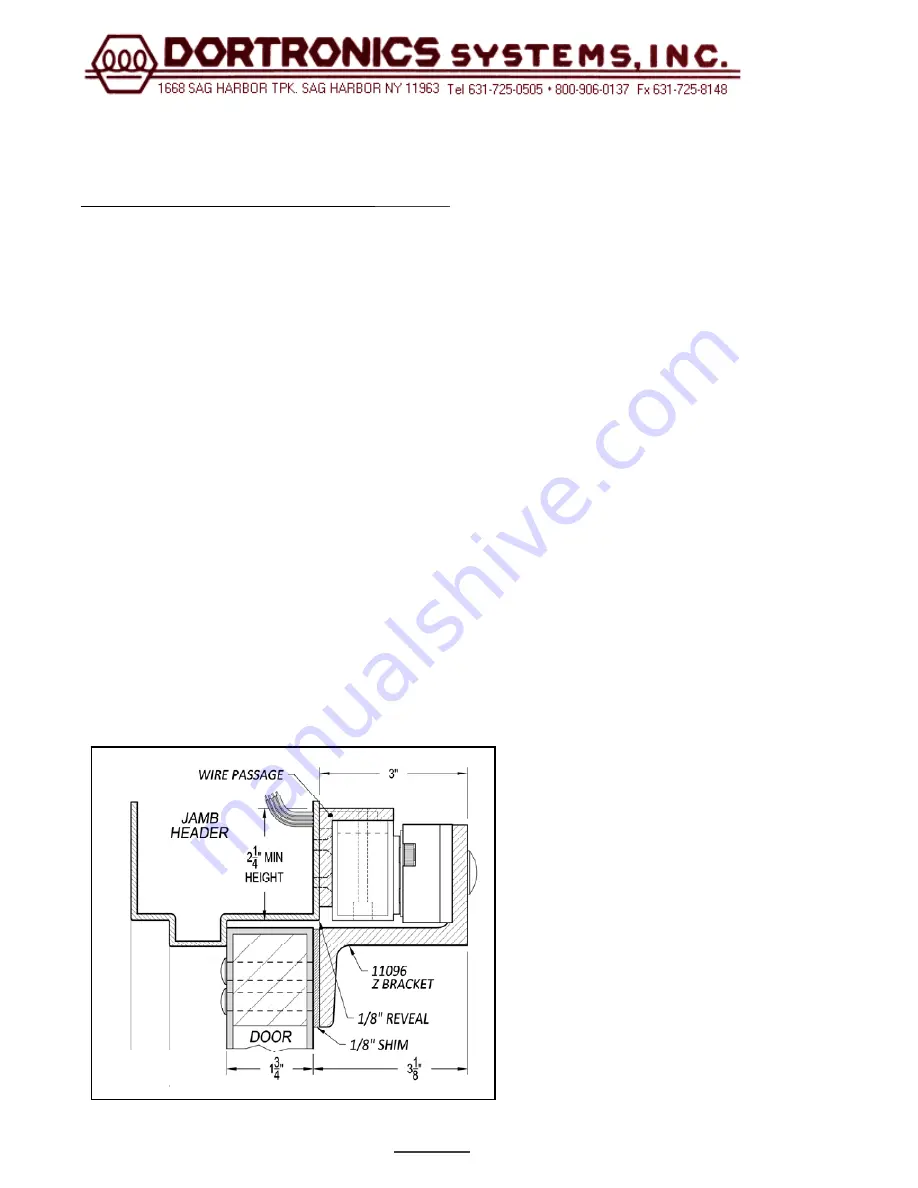

The TJ1107 Series Electro-magnet assembly mounts firmly and rigidly to the header using an L-Bracket. The armature is

held by the Z-Bracket which mounts to the face of the door. Special hardware is used to allow the armature to automatically

align with the face of the electromagnet for maximum holding force when the magnet is energized.

A 2-1/4” wide flat surface is required to mount the TJ1107 series magnet and L-Bracket assembly (see Figure 1). For uneven

or irregular surfaces, the use of shims or filler plates may be required. See the Application Bulletin (attached) for diagrams of

typical door configurations and part numbers for spacers, filler blocks, shims and mounting brackets required for each type of

installation

For hollow metal door and similar installations requiring drilling and tapping, the material thickness should be at least 1/8”.

Sheet metal screws may be used for wood doors and clad doors. For thinly clad doors or wooden doors without sufficient

solid backing, a reinforcing plate may be required.

Before starting, make sure the correct drill template is available for the type of installation planned. Door swing and

construction, door frame material and configuration must be considered before deciding on the proper mounting kit and

method.

STEP 1) MARK AND DRILL JAMB HEADER & INSTALL L-BRACKET

The electromagnet assembly is carried by an L-Bracket that mounts directly to the header – see Figure 1. Before drilling the

header, trial fit the bracket and magnet assembly to make sure that it will mount flush to the bottom of the header with

sufficient clearance for the door to operate without interference.

Use the supplied template to mark the door frame header for drilling. Depending on the material, size the drill bit for

either

#14 Sheet Metal screws or for tapping 1/4-20

machine screws

. Drill clearance hole through header for wire passage.

Break all sharp edges to prevent damage to wire insulation and potential short circuits. Use star washers with machine

screws to prevent loosening over time.

For wood jambs or clad door framing,

the structure must be capable of carrying

the holding force generated by the magnet.

The use of reinforcing material or bolting

Through the header may be required.

MOUNTING INSTRUCTIONS:

TJ1107xEDR TOP JAMB Series

Electro-Magnetic Lock for In-Swing Doors

Figure

1