Splitting Operation

18

1. Put on

protective

clothing /

gear

Wear the following protective clothing and safety gear.

1)

Eye protection.

Always wear safety glasses or goggles when operating the machine.

Pieces of log may fly out and serious eye injury can occur

2)

Boots

. Falling logs can crush feet. Always wear safety shoes or heavy boots when

operating or helping to load logs.

3)

Gloves

. Wear snug fitting gloves without drawstrings or loose cuffs.

4)

Hearing protection

. The use of earplugs or other hearing protection device is

recommended.

5)

No Loose / dangling apparel

. Loose or dangling apparel can become entangled in

moving parts. Never wear jewelry or loose-fitting clothing.

2. Lock &

block

Secure log splitter from unintended movement. Check that:

1)

The jack is locked in the

DOWN

position.

2) The wheels are blocked.

3. Set to

horizontal or

vertical:

a) Set to

Horizontal

position

S

et log splitter into either the horizontal or vertical splitting position

The HORIZONTAL splitting position is used for lighter logs that can be easily loaded onto

the beam. The VERTICAL splitting position is used for light logs as well as heavy logs that

are difficult to load onto the beam.

Note:

Musculoskeletal injury can result from lifting logs onto the log splitter if proper lifting

techniques are not used or the logs are too heavy for a person's size, weight, or strength.

In some cases, logs as small as 8" in diameter and 14" in length may be heavier than what

some persons should be repeatedly lifting onto the splitter.

The use of the vertical splitting position can greatly reduce the need to lift logs onto the

splitter. Employers are advised to consider NIOSH lifting guidelines when assigning

employees to log splitting tasks for an extended period of time.

WARNING

: NEVER change splitting positions with the engine running. You

may contact the muffler and receive serious burns.

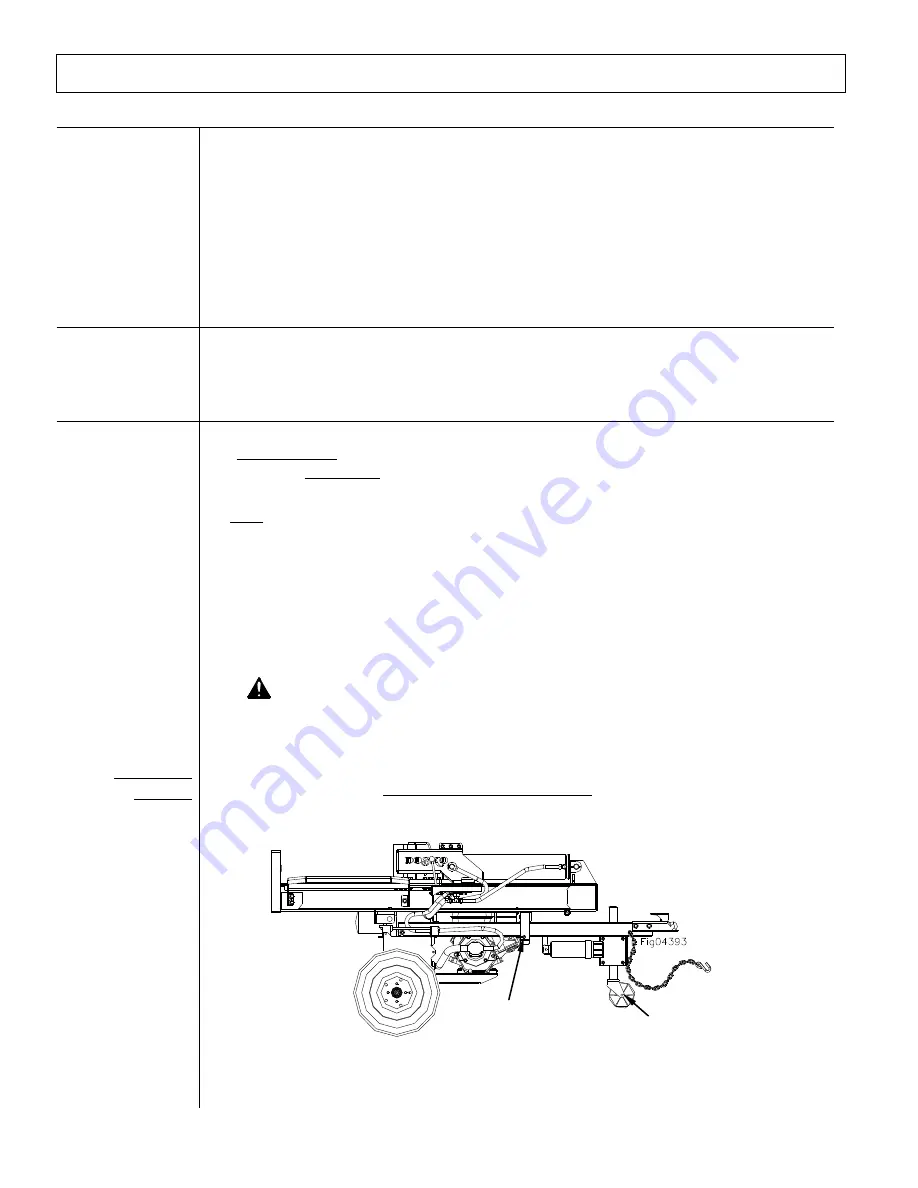

Make sure beam is locked securely in the horizontal position by checking the horizontal

lock.

Horizontal Splitting Position

Horizontal

Lock

Jack in

DOWN

Position