4

Thank you for purchasing our product. We are convinced

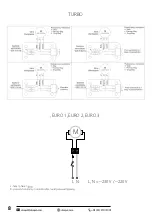

implementation of air steering (TURBO),

that it will meet your expectations. We wish you a trouble-

- flexibility of usage of the fan thanks to the two-speed engine

free exploitation and satisfaction with the choice you made.

(TURBO).

We also encourage you to share with us any remarks you

have regarding the product and our company.

:

(34) 365 98 43 or via

Fans are installed between ventilation ducts of typical

email at:

diameters 100 mm (EURO 1, TURBO 100, POLO 1), 120 mm

(EURO 2), 125 mm (TURBO 125, POLO 2) and 150 mm (EURO

3). After unpacking the fan the condition of the fan's casing

family of our axial-duct fans: POLO, EURO, TURBO.

not touch the tunnel). Above activities are recommended in

order to identify possible damages that could have occurred

:

during transportation. If none of the above mentioned faults

POLO, EURO, TURBO fans effectively remove air together

has been found, assembly of the fan can be started in its

with: unpleasant odors and mites. They are designed to

destination:

support gravitational ventilation. Through a network of

- prepare electrical attachment for the fan,

ventilation ducts of a proper diameter, POLO, EURO and

- place the fan in ventilation duct,

TURBO fans can effectively transport air from/to the rooms

- in case of flexible ducts tighten a duct clip in fan's duct,

of small cubature. These can be public utility as well as

- in case off installation made of PCV fix the fan in the duct and

household rooms such as: bathrooms, toilets, kitchens,

seal with a universal tape TU 50/50,

bedrooms, living rooms, offices, public toilets, restaurants,

- connect the fan to the power supply.

waiting rooms, laundry rooms, drying rooms, shops.

:

:

EURO, POLO, TURBO fans do not require frequent and detailed

- inductive asynchronous single phase motor, adapted for

a year the fan has to be disassembled and cleaned from

continuous operation S-1 characterized by silent operation

deposits as well as an inspection of the engine has to be

in relation to its efficiency,

performed.

- type of bearing: slide bearing,

- casing and propeller made of high quality ABS material.

:

- inductive asynchronous single phase motor, adapted to

In order to remove all impurities from the inside of the fan

continuous operation S-1 characterized by silent operation

please perform the following activities:

in relation to its efficiency,

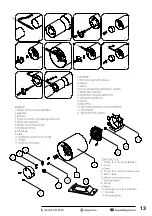

- disconnect the fan from the power supply,

- disassemble the fan,

- casing and propeller made of high quality material ABS,

- in case of significant pollution disassemble the propeller,

- mounting base, which provides fast and easy assembly of

- wash all parts with a damp cloth adding small amount of

the fan to the ground.

detergent, careful not to wet the motor,

Construction of the POLO fan facilitates its assembly in

- re-assemble all dry elements,

telescopic duct system DOSPEL, thanks to implementation

- fix the fan in its destination location,

- connect the fan to the power supply.

TURBO

:

- inductive, asynchronous, single phase, two-speed motor,

Each engine should be subjected to periodical inspections

adapted to continuous operation S-1, characterized by

depending on the conditions in which it operates, however

silent operation in relation to its efficiency,

not less than once every two years. Inspection should include

- casing and propeller made of high quality ABS material,

cleaning and external examination of the engine, protective

- air steering, the application of which allows re-distribution

and starting apparatus. Inspection should be performed by a

of an air stream in a duct, improving parameters of the fan’s

person entitled to do so with appropriate qualifications.

operation,

- type of bearing: slide bearing,

Check the rotational direction of the propeller when

- mounting base, which provides fast and easy assembly of

connected in order to avoid improper operation of the device.

the fan to the ground.

The direction of rotations should correspond to the direction

of the rotation arrow. In case of damage it should be repaired

by a specialist service. Before starting the engine all screw

- very easy assembly,

connections have to be checked and tightened if necessary.

- complies with strict acoustic requirements,

- high efficiency,

The producer reserves the right to introduce constructional

- has an antistatic additive,

changes, arising from the technical progress.

- re-distribution of an air stream in a duct thanks to

EN

4

Product description

K