3.1 Lubricant recommendations

The oil grade will be selected according to the ambient

temperature under which the compressor will be operated.

Between . . . . . . -10°C & 30°C SAE 15 W 40

Below . . . . . . . . -10°C . . . . . .SAE 10 W 40

Above . . . . . . . 30°C . . . . . . .SAE 15 W 50

An oil change must be performed after 10 h of working.

Denial of this item will void the warranty.

With the above recommanded oil, oil change is reques-

ted every 300 working hours or 6 month.

Blackmer recommends the use of BSC oil for the opera-

tion of its screw compressors. Using BSC allow an

increase of the time between oil change to 1 year or 500

working hours.

Blackmer offers an extra year of warranty if only BSC oil

is used inside its compressors.

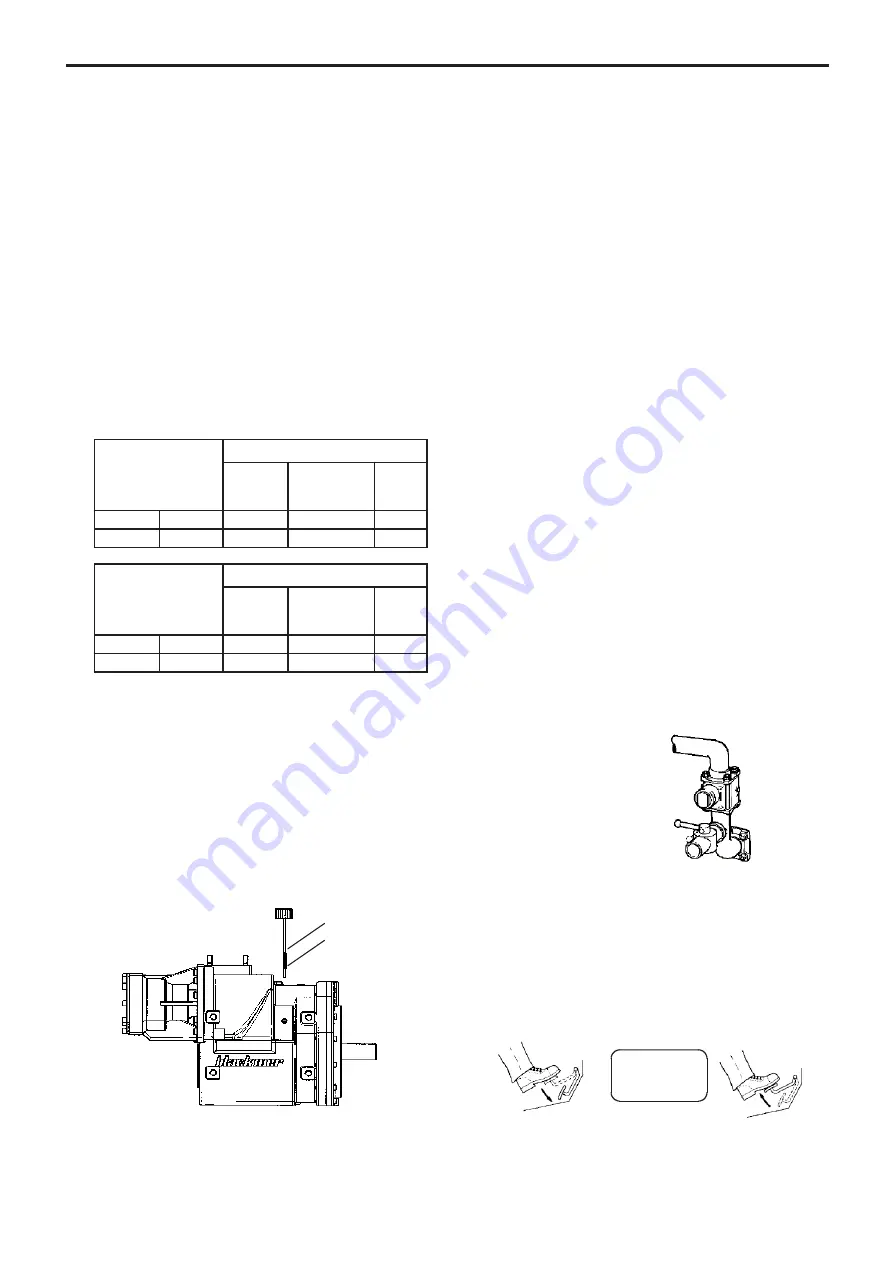

3.2 Before start-up - Filling of Lubricant

Our package are delivered without oil. The use of a com-

pressor with an oil level that is not located between the

two limits indicated by the gauge can lead to important

property damage and serious injuries.

The filling of the oil tank must be made so that the level

is comprised between the minimum and maximum mark

of the gage. For information, the tank size is approxima-

tely 5 liters for TYPHON. Please note that the oil level is

checked after fully tigh-tening the gauge on the filling

tube.

3.3 Start-up procedure

The compressor must be started with the discharge valves

open.

When it is started for the first time, check the compres-

sor rotation direction (clockwise direction for an observer

facing the compressor shaft). Also check rotation speed

(refer to § 1.2. and 1.3).

The compressor shall be started without any counter-

pressure at discharge.

At commissioning, check that the combinations of rota-

tion speed and discharge pressure of the compressors

are in conformity with those indicated in §1.2.

During operation, the temperature of the surface of a

compressor and nearby parts can be in the region of

200°C. The compressor and the parts located nearby are

thus susceptible of provoking serious burns and property

damage. Be careful to not approach elements that are

sensitive to heat and affix plates informing users that the

compressor is hot, in order to prevent any risks of burns.

A transparent self-adhesive label sticker on which

instructions of use are indicated is provided with the

compressor. It should be stamped on the windshield and

filled with the proper information for the driver to know

how to operate properly the package.

3.4 COMPRESSOR START UP PROCEDURE -

Vehicle Mounted

STEP 1

BEFORE starting compressor, open all air valves neces-

sary to vent the tank and compressor to atmosphere.

Verify there is no possibility of operating at pressure

before compressor reaches correct speed.

STEP 2

Start the engine and run will standard speed.

Depress clutch and engage the PTO.

Release the clutch SLOWLY.

Set engine speed to give the correct compressor speed.

PTO

EMBRAYEE

LENTEMENT

ON

SLOWLY

"

OUVERT"

OPEN

Niveau

Maxi

Maxi

Mini

Compressor

With BSC oil

First oil

change

(h)

Oil change

Warranty

period

(year)

TYPHON 20R / 30R

10

500 h

3

MISTRAL 20R / 30R

10

500 h / 1 year

3

Compressor

Without BSC oil

First oil

change

(h)

Oil change

Warranty

period

(year)

TYPHON 20R / 30R

10

300 h / 6 months

2

MISTRAL 20R / 30R

10

300 h / 6 months

2

10/21

NT 1401-F00 12.05 Cold front outlet Intercooler TYPHON e

33.. P

PA

AC

CK

KA

AG

GE

E O

OP

PE

ER

RA

AT

TIIO

ON

N