GTB Series

23

Dimensions and technical information are subject to change without notice

Servo Positioner Rotary Table | Installation

3. Installation

TD‐G17‐0003‐00

11

Use screw

(

High geared type

)

•

The material of the motor mounting flange is made of aluminum material.

Tightening torque grade is DIN6.8.(See Table1)

•

Finally, close the cap of the access hall with a plug.

•

Tap processing for motor mounting is made on the motor mounting flange.

The tap hole depth is double the tap size.

Table3. T

ightening torque table of c

lamp collar screws

Model size

Use screws

Qty

Tightening torque

[N・m]

GTB40

M4x12

2

4.3

GTB63

M5x15

2

8.6

GTB80

M6x20

2

14.7

GTB100

M8x25

2

35.6

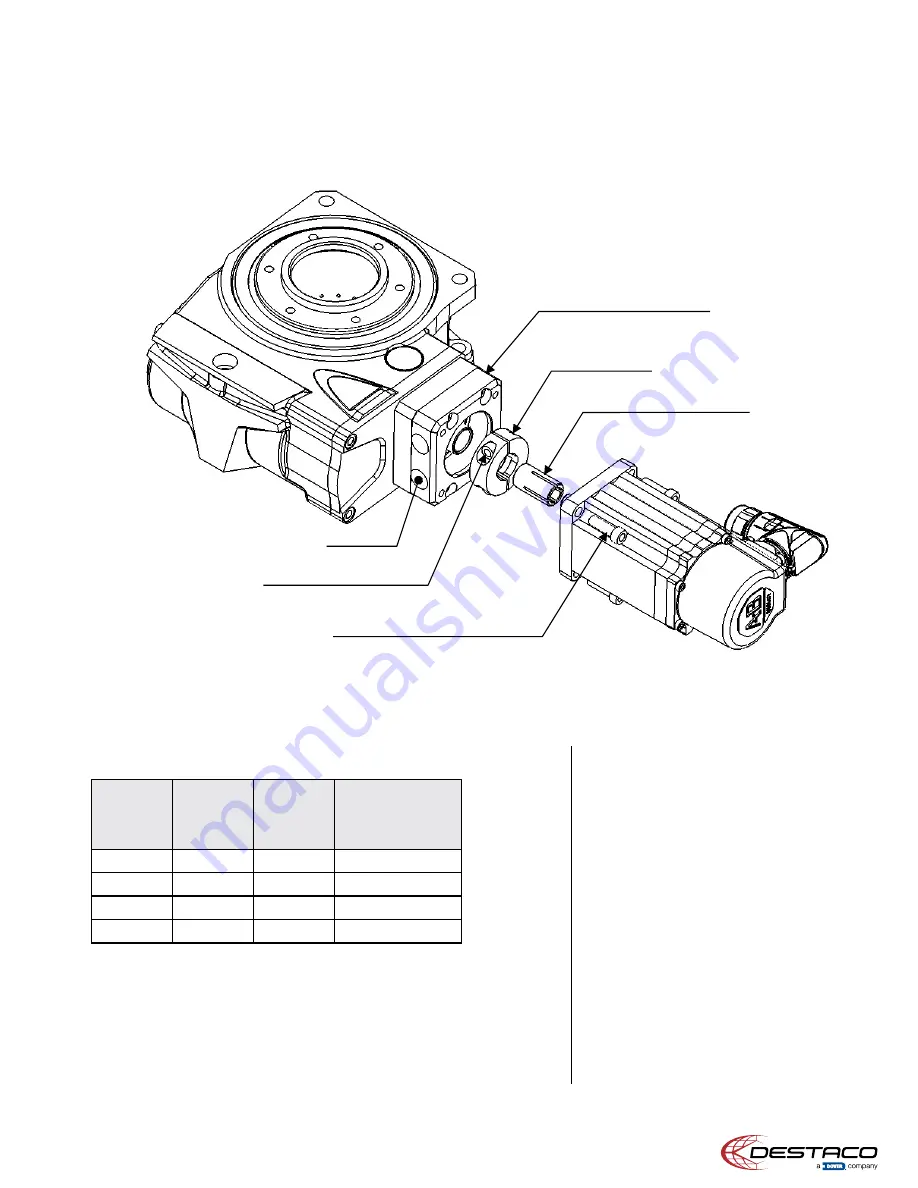

Clamp collar

Motor shaft bushing

Motor mounting screws

(Not attached )

Clamp collar screws

Plug

Motor mounting flange

• The material of the motor mounting flange is made of aluminum

material. Tightening torque grade is DIN6.8 (See Table 1).

• Finally, close the cap of the access hall with a plug.

• Tap processing for motor mounting is made on the motor

mounting flange. The tap hole depth is double the tap size.

Use Screw (High Geared Type)

Table 3:

Tightening torque table of clamp collar screws

Model

Size

Use

Screws

Qty

Tightening

Torque

[Nm]

GTB40

M4x12

2

4.3

GTB63

M5x15

2

8.6

GTB80

M6x20

2

14.7

GTB100

M8x25

2

35.6

5. How to remove the motor

Follow these steps to follow if you are

removing the motor from the unit.

1. Remove the access hole plug.

2. Turn the clamp collar screws

toward the access hole of the motor

mounting flange. (Use the JOG

operation mode of the motor)

3. Remove the clamp collar screws

(Untighten two screws equally)

4. Remove the motor mounting screws

5. Remove the motor