OM/SM-AH-CE

18

The gas burners are protected by an

electronic flame failure device which

incorporates automatic ignition of the

burners and instant shut-off of the gas

supply to the burners should a gas supply

interruption occur.

Options available with listed models are:

1.

Three inch (7.6 cm) tangent draw-off

valve. (Factory-installed option)

2.

Basket inserts.

3.

Water filler with swing spout and

bracket.

4.

Kettle brush kit.

5.1.2

Operational and Maintenance Safety

CAUTION

BE SURE ALL OPERATORS READ,

UNDERSTAND AND FOLLOW OPERATING

INSTRUCTIONS, CAUTIONS AND SAFETY

INSTRUCTIONS IN THIS MANUAL.

WARNING

INSTALLATION OF THE UNIT MUST BE

DONE BY PERSONNEL QUALIFIED TO

WORK WITH ELECTRICITY, GAS AND

PLUMBING IN ACCORDANCE WITH ALL

APPLICABLE CODES.

BEFORE REPLACING ANY PARTS,

DISCONNECT THE UNIT FROM THE

ELECTRIC POWER SUPPLY AND CLOSE

THE MAIN GAS COCK. ALLOW FIVE

MINUTES FOR UNBURNED GAS TO VENT.

TO PREVENT SHOCKS, ALL APPLIANCES

WHETHER GAS OR ELECTRIC, MUST BE

EARTHED.

5.2 Lighting and Operation

5.2.1

Initial Kettle Lighting and Operational

require venting. (This will require a

Readiness Check

service call).

After the AH Kettle has been installed according

6.

Switch the On/Off switch to the "On"

to service and installation instructions, perform

position. The "power on" neon will

initial start-up as a test to ensure that the unit is

illuminate.

operating correctly. Follow the steps below.

Refer to the picture for identification of AH

7.

Turn the thermostat dial to the required

controls and indicators.

setting.

1.

Remove all literature and packing

8.

After 10-15 seconds the burners should

material from the interior and exterior of

light. The "burners on" neon will

the unit.

illuminate.

2.

Make sure gas and electricity supplies

9.

In the event the burners do not light, or

are switched on.

go out as indicated by the illumination of

3.

Ensure that the kettle is filled with water

off. Wait approx 1 minute. Press lockout

before lighting.

reset switch and repeat steps (4) to (8).

4.

Check the water level in the jacket. The

level should be between the lines on the

gauge glass. If the level is low, the

jacket water level will be required to be

topped up. (This will require a service

call).

5.

Check the pressure gauge. If the gauge

does not show sufficient vacuum (that is,

20 to 30 below zero), the jacket will

the lockout indicating neon, turn the unit

WARNING

AVOID CONTACT WITH THE FLUE.

SURFACES ARE VERY HOT AND WILL

CAUSE BURNS.

DO NOT OBSTRUCT FLUE EXHAUST

OPENING.

Summary of Contents for GROEN AH-20

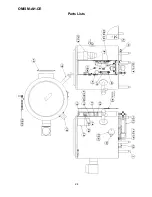

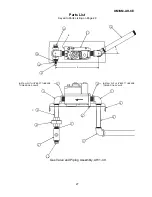

Page 23: ...OM SM AH CE 23 ...

Page 24: ...OM SM AH CE 24 Parts Lists ...