OM/SM-AH-CE

6

1.8 Total Gas Rate

NOTE: With reference to the gas rate, pressure

Model

(G20&

(G31)

Natural

Propane

G25) KW

KW

Natural

Propane

BTU/hr

BTU/hr

AH-20

22

75,100

22

75,100

AH-40

25

85,300

22

75,100

AH-60 &

AH-80

40

136,500

40

136,500

1.9 Injector Diameters-Natural & Propane Gas

Model

Gas G20 Gas G25 Gas G31

Natural

Natural Propane

(mm)

(mm)

(mm)

No. of

Orifices

(Injectors)

AH-20

4.39

4.70

2.64

1

AH-40

4.57

4.90

2.64

1

AH-60 &

AH-80

5.94

6.75

3.57

1

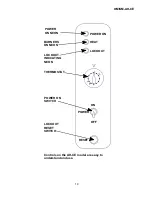

1.10

Gas Pressure Adjustment

A pressure test point is fitted on the burner

manifold and on the gas control valve.

Model

AH-20

AH-40

AH-60 &

AH-80

NATURAL

GAS G20

mbar

8.75

8.75

8.75

in. WC

3.5

3.5

3.5

NATURAL

GAS G25

mbar

8.75

8.75

7.0

in. WC

3.5

3.5

2.8

PROPANE

GAS G31

mbar

25

25

25

in. WC

10

10

10

adjustments and conversions, this appliance is

CE-approved for use with the following gases:

a) G20 natural gas may be supplied to the

appliance in Austria, Belgium, Denmark,

Finland, France, Germany, Greece, Iceland,

Ireland, Italy, Luxembourg, Norway, Portugal,

Spain, Sweden, Switzerland and the United

Kingdom.

b) G25 natural gas may be supplied to the

appliance in Belgium, France and the

Netherlands.

c) G31 propane gas may be supplied to the

appliance in France, Germany, Ireland, the

Netherlands, Portugal, Spain, Switzerland,

and the United Kingdom.

Use of the appliance with non-approved gases in a

listed country, or use in other countries will void CE

certification.

1.11 Burner Adjustment

The burner has a primary air adjustment. The gap

should be 1/4" (6.35 mm) to 3/8" (9.53 mm).

Section 2

Assembly and Commissioning

2.1 Assembly

2.3

Electrical Supply

a) Unpack the appliance.

Before commissioning the appliance, ensure that the

b) Place on a firm, level floor. Adjust and fix

relevant regulations. (Paragraph 1.5)

feet.

Caution:

Shipping straps are under tension and

can snap back when cut. Take care to avoid

personal injury or damage to the unit by staples

left in the walls of the carton.

2.2 Gas Supply

Connect the unit to the gas supply and test for gas

soundness. For the part of the integral gas supply

down stream of the gas valve, leak detection

spray or some solution may be used with the

burners lit.

Caution:

Ensure that the pan contains liquid when

the burners are alight.

electrical installation has been carried out to the

THIS APPLIANCE MUST BE EARTHED.

2.4

Jacket Water Level/Jacket Pressure

a) Ensure the water level is correct in the jacket, by

confirming that the level is between the marks on

the gauge glass. If the water is low, follow the

instructions under "Jacket Filling" in the servicing

section of this manual.

b) Check the pressure gauge. If the gauge does not

show 20 or more inches of vacuum (that is, a

reading of 20 to 30 below zero) see "Jacket

Vacuum" in the servicing section of this manual.

2.5

Pre-Commissioning Check

Summary of Contents for GROEN AH-20

Page 23: ...OM SM AH CE 23 ...

Page 24: ...OM SM AH CE 24 Parts Lists ...