OM-NHFP

OM-NHFP

4

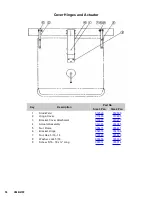

Equipment Description

Groen NHFP and NHFP(E) Gas Fired Braising

Pans provide a stainless steel pan equipped with

heat transfer fins, burner/combustion chamber,

power tilting mechanism, thermostatic controls,

and hinged cover. The Braising Pan serves as a

braising unit, griddle, fry pan, oven, kettle,

bain

marie,

or food warmer and server. It can also be

adapted for use as a steamer.

The pan body is constructed of heavy-duty

stainless steel welded into one solid piece, with a

polished interior and a semi-deluxe finish on the

exterior. A pouring lip is welded into the front

wall. The cooking surface is a stainless steel

clad plate fitted with welded heat transfer fins

that assure uniform heat transfer over the entire

surface. The gas burner/combustion chamber

supplies the heat.

The pan is tilted forward by an electrically

powered actuator mechanism. A three-position

switch on the front of the control console gives

the operator positive, smoothly operating control

of tilting. When the pan is tilted, the burners shut

off automatically.

The thermostat provides automatic control of

cooking temperature. The thermostat dial on the

front of the control console turns the heat on or

off and sets the pan temperature.

A vented, heavy gauge, one-piece, stainless

steel cover with rear condensate drip shield on

its underside is standard on the Braising Pan.

A fully enclosed, spring-type actuator

counterbalances the cover to keep it opened or

closed. The cover opens to the back and is

hinged to the frame, so that it moves

independently of the pan body.

Different ignition systems distinguish the basic

models. Model NHFP uses a thermopile-

controlled, standing pilot flame to light the main

burner. Model NHFP(E) ignites the main burner

directly with an electrically heated hot surface

igniter.

The following models and options are available:

Model

Pan Body Dimensions, Inches

Left to

Right

Depth

Firing

Rate

NHFP-3

31¾

9

104,000

BTU/hr

NHFP(E)-3

31¾

9

104,000

BTU/hr

NHFP-4

41

d

9

144,000

BTU/hr

NHFP(E)-4

41

d

9

144,000

BTU/hr

Optional Equipment (Any Model)

1. Fill faucet with swing spout

2. Model REJ Steamer Insert

3. Caster mounting kit (factory installation

only)

4. Two inch tangent draw-off