C2

CASE DIMENSIONS

C L

NOTES:

* STUB-UP AREA

** RECOMMENDED STUB-UP CENTERLINE FOR ELECTRICAL AND HUB DRAINS

• ENDS ADD APPROXIMATELY 1 INCH TO CASE HEIGHT

• WIRING-TO-THE-TOP- ADDS APPROXIMATELY 4 INCHES TO CASE HEIGHT

• A 2" MINIMUM AIR GAP IS REQUIRED BETWEEN THE REAR OF THE CASE AND A WALL

• SUCTION LINES: 1/2" (4DR OR LESS); 5/8" (5DR & 6DR)

• LIQUID LINES: 1/2" (ALL LENGTHS); BOTH ELECTRIC & HOT GAS DEFROST

• AVAILABLE SHELF SIZES: WIRE SHELVES 16", 18", 20" & 22"; SOLID SHELVES 18", 20" & 22"

• TOP SHELF MUST BE 20" OR SHORTER

• RECOMMENDED CONFIGURATION IS 20" SHELF AND 4 22" SHELVES BELOW TOP SHELF

• DASHED LINES SIGNIFY AREA INSIDE BASE RAIL BEHIND KICK-PLATE

WIRING TO THE TOP

(OPTIONAL)

1 1/2" PVC DRAIN

CONNECTION

REFRIGERATION

FRONT OF CASE

26 13/16 in**

[68.1 cm]

23 1/4 in

[59.1 cm]

1 1/2 in [3.8 cm] {END}

8 11/16 in [22.1 cm]

COIL

PLENUM

23 1/4 in

[59.1 cm]

22 in

[55.8cm]

31 in

[81.0 cm]

34 7/8 in [88.5 cm]

5 1/8 in

[13.1 cm]

16 1/4 in

[41.3 cm]

7 1/2 in

[19.1 cm]

64 3/8 in

[163.5 cm]

(Frame Height)

62 3/8 in

[158.4 cm]

(Door Height)

59 in

[149.9 cm]

22 in

[55.8 cm]

31 in [81.0 cm]

4 in

[10.2 cm]

31 in [76.2 cm] {1 Door}

60 in [152.4 cm] {2 Door}

90 in [228.6 cm] {3 Door}

120 in [304.8 cm] {4 Door}

150 in [381.0 cm] {5 Door}

180 in [457.2 cm] {6 Door}

81 in

[205.7 cm]

83 in

[210.8 cm]

34 5/8 in [88.0 cm]

34 7/8 in

[88.5 cm]

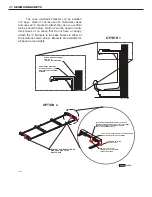

STREAMLYNE BUMPER OPTION

7 in

[17.7 cm]

1/2 BUMPER OPTION

7 7/8 in

[20 cm]

6 7/16 in*

[16.3 cm]

23 3/16 in

[58.1 cm]

ELECTRICAL

JUNCTION BOX

(WIRING PER LOCAL CODES)

22 in

22 in

22 in

22 in

20 in

3 1/8 in [7.9 cm]

REAR REFRIGERATION

(14" OFF OF FLOOR)

PIPING TO THE TOP

(OPTIONAL)

8 in [20.3 cm]

14 in [35.6 cm]

Summary of Contents for Hillphoenix ONRZ

Page 23: ...ELECTRIC DEFROST 1 PHASE E2 ELECTRICAL WIRING ...

Page 24: ...E3 ELECTRIC DEFROST 3 PHASE ELECTRICAL WIRING ...

Page 25: ...E4 ELECTRIC DEFROST HOT GAS ELECTRICAL WIRING ...

Page 31: ...J2 SEISMIC BRACKETS 5 BRACKETS ...

Page 32: ...J3 SEISMIC BRACKETS 7 BRACKETS ...

Page 33: ...J4 SEISMIC BRACKETS 11 BRACKETS ...