SECTION 1 GENERAL INFORMATION

8

0855849enf 6/08

package

See product.

print station

The complete assembly consisting of the enclosure, electrical

components, user interface module, and ink delivery module.

product

The material or item onto which the coder prints. Also called carton, case,

package, or packaging.

product ID reader

A bar code reader that scans product information to determine which job

file to print.

purge

The forcing of trapped air and hot ink through the jet array for a few

seconds.

reader

See bar code reader.

registration

The location of the printed image on the package, based on whether the

print trigger is determined by a sensor or fixed spacing setting.

reservoir

A receptacle inside the printhead that stores ink.

SC

The Model 5200 SC and 5400 SC have an ink delivery module that uses

ink blocks instead of ink bottles.

SICK

A manufacturer of bar code readers which interface with the coder.

signal tower

An optional device consisting of a set of lamps to indicate coder status.

Formerly called fault beacon.

SSCC

Serialized Shipping Container Code.

umbilical

The assembly including the ink line, electrical line, and vacuum line that

connects the printhead to the enclosure.

user interface module

The keypad and display mounted to the top of the enclosure for the user to

enter and receive information about the coder.

VPC

Vacuum Pressure Controller.

warning

A fault that generates a message on the display, but does not stop printing.

Summary of Contents for Markem-Imaje 5000 Series

Page 1: ...o p e r a t i o n g u i d e ...

Page 2: ......

Page 4: ...iv 0855849enf 6 08 ...

Page 7: ...Model 5200 5400 Operation Guide SECTION 1 General Information ...

Page 8: ......

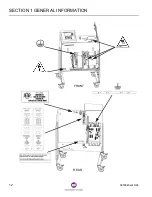

Page 18: ...SECTION 1 GENERAL INFORMATION 12 0855849enf 6 08 FRONT REAR ...

Page 24: ......

Page 25: ...Model 5200 5400 Operation Guide SECTION 2 Basic Operation ...

Page 26: ......

Page 38: ......

Page 39: ...Model 5200 5400 Operation Guide SECTION 3 Printing ...

Page 40: ......

Page 55: ...Model 5200 5400 Operation Guide SECTION 4 Cleaning and Care ...

Page 56: ......

Page 61: ...Model 5200 5400 Operation Guide SECTION 5 Troubleshooting ...

Page 62: ......

Page 67: ...User Documentation Department ...