MG586 Introduction

4

W450030A 09/09

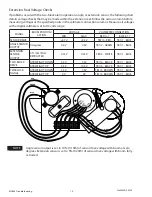

Operator’s Display Console

Warning/Alarm Indicators

The red two-block lamp will illuminate when a two-

block condition occurs.

The yellow pre-warning lamp will illuminate at 90% of

rated capacity.

When the load reaches or exceeds 100% of rated

capacity, the red overload warning lamp will

illuminate along with the yellow pre-warning lamp,

when this occurs, the computer will implement a

function kick-out, which in turn, disables the boom

down, winch up, and extend out functions.

Display Windows

The current rated capacity for the crane in the current configuration will be displayed in the rated capacity

window as well as the percent of rated capacity shown as a meter which progresses to the right as the load

increases. Refer to “Normal Operation” Section of this manual.

The setup codes have been pre-configured to match the setup of the crane. The setup codes are shown as

well as the parts-of-line. Refer to “Configuration Selection” Section of this manual.

The information window shows crane specific information regarding boom length, boom angle, and working

radius, along with the load on hook. In addition, information regarding any warnings or alarms will be

displayed in this window. If the system has any internal faults, it will display “!WARNING! SYSTEM FAULT” in the

information window. The specific fault messages can be viewed by pressing the

83$552:

or

'2:1$552:

key. Refer to “System Fault Messages” Section of this manual.

5DWHG&DSDFLW\

6HWXS&RGH

,QIRUPDWLRQ

W450030r2 03/16

Summary of Contents for MG586

Page 2: ......

Page 3: ...W450030r2 03 16 ...

Page 25: ...ATB Cable Replacement for A240700 Reel Assembly ...

Page 26: ...SLIP RING W450030r2 03 16 ...

Page 27: ...W450030r2 03 16 ...

Page 28: ...SLIP RING W450030r2 03 16 ...

Page 29: ...W450030r2 03 16 ...