2 OM-ECOARCH

IMPORTANT - READ FIRST - IMPORTANT

CAUTION: DO NOT ATTEMPT TO SERVICE THIS UNIT YOURSELF AS REMOVING COVERS

MAY CAUSE UNNECESSARY EXPOSURE TO DANGEROUS VOLTAGE.

CAUTION: NEVER CONNECT THE UNIT TO A POWER SOURCE WHILE STANDING IN

WATER. WET HANDS AND WET FLOORS SHOULD BE AVOIDED WHEN

CONNECTING ANY ELECTRICAL APPLIANCE TO A POWER OUTLET.

CAUTION: FANS MAY HAVE MULTIPLE POWER CONNECTIONS. MAKE SURE ALL FANS

ARE ISOLATED FROM POWER PRIOR TO PERFORMING MAINTENANCE.

8. For make-up air hoods, the supply collar with built-in UL listed damper and

air volume damper must be installed per instructions on collar.

9. Provide a removable service door in supply duct near damper (See Fig. 4).

Installation Instructions

INSTALLATION REQUIREMENTS

FOR ALL AVTEC ECOARCH

VENTILATION HOODS

CANOPIES

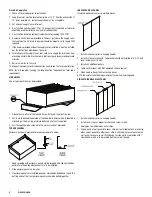

Figure 1

Figure 2

HANGER BRACKET DETAIL

S.S. NUT & BOLT

BY OTHERS

HANGER ROD

HANGER ROD

NUT

Avtec hoods are provided with adjustable hanging brackets designed to receive 1/2”

threaded rod with a 1/2” nut and washer. Supporting rods must be connected to all factory

installed brackets. Recommended hanging height is 6’-6” above finished floor for

canopies. Low side wall ventilators should be installed directly upon a Avtec base or on a

rerated wall. If wall mounted, the bottom of the vent should be 36” above finished floor.

ALL AVTEC VENTILATION SYSTEMS MUST BE INSTALLED IN ACCOR-

DANCE WITH NFPA-96, REMOVAL OF SMOKE AND GREASE-LADEN

VAPORS FROM COMMERCIAL COOKING EQUIPMENT.

1. Check all local codes prior to installation. Special requirements may be necessary

depending upon building material construction.

2. Move crated hood to location of installation and very carefully uncrate hood.

3. Raise hood to proper hanging height.

4. Suspend hood from adequate roof supports using 1/2

"

threaded rods with nuts

and washers (See Fig. 1).

5. Level hood left to right and front to back.

6. Brackets are provided for hoods which are to be installed end to end or back to back.

Bolt brackets together using 3/8

"

bolt through holes provided (See Fig. 2).

7. Install C channel where the ends of the hood meet and install T moldings on front

face of hoods where they join. High temperature silicone can be used to install

channel and T moldings (See Fig. 3).

8. For make-up air hoods, the supply collar with built-in UL listed damper and

air volume damper must be installed per instructions on collar.

9. Provide a removable service door in supply duct near damper (See Fig. 4).

Figure 3

Figure 4

EXHAUST DUCT

INSULATED

PRE-DRILLED

HOLE, ACCEPTS

UP TO 1/2"ÿ ROD

PRE-DRILLED

HOLE, ACCEPTS

5/16" BOLT

HOOD

ANGLE

OF HOOD

NOTE: HOLES DRILLED THROUGH HOOD ANGLE BY

INSTALLER AFTER BRACKET ATTACHMENT

POINTS HAVE BEEN DETERMINED.

HOOD FACE

T-MOLDING

C-CHANNEL

SUPPLY DUCT

ACCESS

PANEL

FIRE DAMPER &

VOLUME CONTROL

DAMPER

FLUID WELD

Installation Instructions

INSTALLATION REQUIREMENTS

FOR ALL AVTEC ECOARCH

VENTILATION HOODS

CANOPIES

Figure 1

Figure 2

HANGER BRACKET DETAIL

S.S. NUT & BOLT

BY OTHERS

HANGER ROD

HANGER ROD

NUT

Avtec hoods are provided with adjustable hanging brackets designed to receive 1/2”

threaded rod with a 1/2” nut and washer. Supporting rods must be connected to all factory

installed brackets. Recommended hanging height is 6’-6” above finished floor for

canopies. Low side wall ventilators should be installed directly upon a Avtec base or on a

rerated wall. If wall mounted, the bottom of the vent should be 36” above finished floor.

ALL AVTEC VENTILATION SYSTEMS MUST BE INSTALLED IN ACCOR-

DANCE WITH NFPA-96, REMOVAL OF SMOKE AND GREASE-LADEN

VAPORS FROM COMMERCIAL COOKING EQUIPMENT.

1. Check all local codes prior to installation. Special requirements may be necessary

depending upon building material construction.

2. Move crated hood to location of installation and very carefully uncrate hood.

3. Raise hood to proper hanging height.

4. Suspend hood from adequate roof supports using 1/2

"

threaded rods with nuts

and washers (See Fig. 1).

5. Level hood left to right and front to back.

6. Brackets are provided for hoods which are to be installed end to end or back to back.

Bolt brackets together using 3/8

"

bolt through holes provided (See Fig. 2).

7. Install C channel where the ends of the hood meet and install T moldings on front

face of hoods where they join. High temperature silicone can be used to install

channel and T moldings (See Fig. 3).

8. For make-up air hoods, the supply collar with built-in UL listed damper and

air volume damper must be installed per instructions on collar.

9. Provide a removable service door in supply duct near damper (See Fig. 4).

Figure 3

Figure 4

EXHAUST DUCT

INSULATED

PRE-DRILLED

HOLE, ACCEPTS

UP TO 1/2"ÿ ROD

PRE-DRILLED

HOLE, ACCEPTS

5/16" BOLT

HOOD

ANGLE

OF HOOD

NOTE: HOLES DRILLED THROUGH HOOD ANGLE BY

INSTALLER AFTER BRACKET ATTACHMENT

POINTS HAVE BEEN DETERMINED.

HOOD FACE

T-MOLDING

C-CHANNEL

SUPPLY DUCT

ACCESS

PANEL

FIRE DAMPER &

VOLUME CONTROL

DAMPER

FLUID WELD

Installation Instructions

INSTALLATION REQUIREMENTS

FOR ALL AVTEC ECOARCH

VENTILATION HOODS

CANOPIES

Figure 1

Figure 2

HANGER BRACKET DETAIL

S.S. NUT & BOLT

BY OTHERS

HANGER ROD

HANGER ROD

NUT

Avtec hoods are provided with adjustable hanging brackets designed to receive 1/2”

threaded rod with a 1/2” nut and washer. Supporting rods must be connected to all factory

installed brackets. Recommended hanging height is 6’-6” above finished floor for

canopies. Low side wall ventilators should be installed directly upon a Avtec base or on a

rerated wall. If wall mounted, the bottom of the vent should be 36” above finished floor.

ALL AVTEC VENTILATION SYSTEMS MUST BE INSTALLED IN ACCOR-

DANCE WITH NFPA-96, REMOVAL OF SMOKE AND GREASE-LADEN

VAPORS FROM COMMERCIAL COOKING EQUIPMENT.

1. Check all local codes prior to installation. Special requirements may be necessary

depending upon building material construction.

2. Move crated hood to location of installation and very carefully uncrate hood.

3. Raise hood to proper hanging height.

4. Suspend hood from adequate roof supports using 1/2

"

threaded rods with nuts

and washers (See Fig. 1).

5. Level hood left to right and front to back.

6. Brackets are provided for hoods which are to be installed end to end or back to back.

Bolt brackets together using 3/8

"

bolt through holes provided (See Fig. 2).

7. Install C channel where the ends of the hood meet and install T moldings on front

face of hoods where they join. High temperature silicone can be used to install

channel and T moldings (See Fig. 3).

8. For make-up air hoods, the supply collar with built-in UL listed damper and

air volume damper must be installed per instructions on collar.

9. Provide a removable service door in supply duct near damper (See Fig. 4).

Figure 3

Figure 4

EXHAUST DUCT

INSULATED

PRE-DRILLED

HOLE, ACCEPTS

UP TO 1/2"ÿ ROD

PRE-DRILLED

HOLE, ACCEPTS

5/16" BOLT

HOOD

ANGLE

OF HOOD

NOTE: HOLES DRILLED THROUGH HOOD ANGLE BY

INSTALLER AFTER BRACKET ATTACHMENT

POINTS HAVE BEEN DETERMINED.

HOOD FACE

T-MOLDING

C-CHANNEL

SUPPLY DUCT

ACCESS

PANEL

FIRE DAMPER &

VOLUME CONTROL

DAMPER

FLUID WELD

FIGURE 1

FIGURE 2

FIGURE 3

FIGURE 4

ECOARCH CANOPIES EQUIPPED WITH UV ASSEMBLY

If your EcoArch hood comes equipped with an UV assembly please refer to the

following steps.

General CAUTIONS & Guidelines:

• Installation of UV Exhaust canopies must be completed by HVAC ventilation

system contractors or employees trained and qualified to do ventilation hood

and exhaust system installation.

• All Fire Suppression System work must be completed by contractors or

employees trained and qualified to do commercial kitchen exhaust hood fire

suppression system installation.

• All work must conform to local and national building and NFPA 96 codes and

requirements.

• This document covers installation of the UV mechanical components and

electric connections.

• Electric work must be performed by licensed contractors in accordance with

the current National Electric Code and all national, regional and local codes

that apply.

• Read and review these instructions BEFORE attempting to install this unit.

For best results, follow the installation sequence…as described.

Follow steps 1-7 as outlined for standard EcoArch canopy installation under

Installation Instructions previously provided.

8. Install grease extractors as shown in (Fig. 5). Be certain the extractors are

seated properly as the UVc bulb will not operate without safety contacts

being engaged.

9. Open door on face of canopy by twisting the supplied locking handle in order

to install UVc bulb per supplied diagram. Be certain to close door tightly and

engage handle latch in order to engage safety contacts. UVc bulb will not

operate without safety contacts engaged.

10. Check to see that pressure switch tubing is installed on the low port of

switch and the port on top of the hood located in the s/s enclosure.

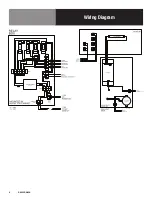

11. Install power to UV system as described in Electrical section. See wiring

diagram at end of this document.

Modules (Figure 5)