4 OM-ECOARCH

Fresh Air Supply Fan

1. Check all local codes prior to installation.

2. Supply fan inlet must be located to minimum 10’-0” from the exhaust fan. If

10’ is not possible a 3’ vertical separation may* be acceptable.

3. Cut and seal supply fan curb to roof.

4. Duct shall be constructed of 22 or 24 gauge steel. Insulated duct material

should be used to eliminate frost and/or condensation.

5. Duct shall be sized to provide air velocities not exceeding 1200 FPM.

6. A volume control damper, provided in the duct just above the supply collar

that contains the UL listed re damper, should be properly set to supply CFM

required.

7. If the hood is provided without the supply collar installed, it must be installed

per the instructions provided on the collar.

8. Carefully place the supply fan on roof curb. Face supply fan inlet away from

prevailing winter wind. Electrical back draft damper is recommended in cold

climates.

9. Bolt or screw fan to fan curb.

10. Make all necessary electrical connections and check fan for proper rotation.

NOTE: Fan will supply air running in wrong direction. *Dependent on local code

requirements.

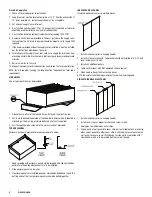

SIDE SKIRTS

One or two side skirts may be provided.

1. Side skirts are offset at the top and have a 90° bend inward at the rear.

2. Skirts are to overlap the outside of the hood. Bolts and acorn nuts should be

attached per the drawing (stainless bolts and acorn nuts supplied).

3. Skirt flange should be screwed to the wall (screws not provided).

TOP ENCLOSURES

Enclosure panels are provided for exposed side(s) of hood(s).

1. Hoods ordered with enclosure panels will be shipped with clips installed on

perimeter of hood top where panels are to be installed.

2. Slide enclosure panel under clips.

3. If enclosure panels are installed on one or more hoods butted end to end, the

butting ends of the front enclosure panels should be bolted together.

INSULATED WALL PANEL

Insulated wall panel comes in multiple pieces.

1. Install wall panels prior to hanging hood(s).

2. Install first panel at one end. Top of panel should be installed 6’-6” A.F.F. and

level. Screw panel to wall.

3. Install any additional panels

4. Caulk vertical seam with NSF approved silicone sealant.

5. When hood is hung it will rest on top panel.

NOTE: Be careful to not damage wall panel face when installing hood.

SINGLE THICKNESS WALL PANEL

1. Install wall panels prior to hanging hood(s).

2. Install seam strips at proper locations and screw to wall.

3. Apply glue to wall between seam strips.

4. Slip one end of wall panel into seam strip, pull out middle of panel and slip

other end of panel into other seam strip. Gently apply pressure over entire

wall panel to secure to wall. Wall bands for side walls are provide with 1”

return bend, which is to be located behind rear wall panels.