5 OM-ECOARCH

START/CHECK/BALANCE

DIRECT DRAW HOODS

1. Close all doors and windows.

2. Operate all exhaust fans, even fans serving other hoods, make-up air units

and building HVAC.

3. Turn on all cooking equipment under the hood to preheat to operating

temperature.

4. Produce large quantities of smoke.

5. Observe capture of vapors.

6. If all vapors are not captured, increase exhaust fan RPM.

7. Check air pressure in kitchen. Pressure must be negative relative to dining

room pressure.

8. Air velocities entering the kitchen from the dining room should not exceed

100 FPM.

No air should be moving toward the dining area.

9. Repeat steps 6 and 7 until all vapors are captured.

10. Same as step 7 with bottom of next section.

NOTE: The exhaust and supply (if any) air flow rates were established under

controlled laboratory conditions, and greater exhaust and/or lesser supply air

may be required for complete vapor and smoke removal in specific installations.

MAKE-UP AIR HOODS EXHAUST FAN(S)

1. Open all doors and/or windows leading to outside.

2. Start the exhaust fan only. Do not run the supply fan or make-up unit.

3. Refer to drawings and/or UL information label on hood for proper CFM

requirements.

4. Adjust speed of exhaust fan to obtain proper air velocities and CFM through

grease filters.

Final Balance

1. Close all doors and windows.

2. Operate all exhaust fans even those serving other hoods, supply fans, make-

up air unit and building HVAC system.

3. Turn on all cooking equipment under the hood and preheat to operating

temperature.

4. Produce large quantities of smoke or steam.

5. Observe capture of vapors.

6. If all vapors are not totally captured, fine tune the system by adjusting the

air volume control damper installed in the supply collar. Slightly reduce the

amount of supply air directed under the hood until full capture is obtained.

SUPPLY FAN OR MAKE-UP AIR UNIT

1. Start the supply fan and/or make-up unit only. Do not run the exhaust fan.

2. Refer to drawings or UL information label on hood for proper CFM

requirements.

PERIODIC MAINTENANCE

WARNING: ELECTRICAL SHOCK HAZARD! DISCONNECT POWER BEFORE SERVICING.

REPLACE ALL PARTS AND PANELS BEFORE OPERATING. FAILURE TO DO

SO CAN RESULT IN DEATH OR ELECTRICAL SHOCK.

CAUTION: MAKE SURE ALL COOKING EQUIPMENT, THE EXHAUST HOOD AND UVC

EXHAUST AIR CLEANER HAVE BEEN TURNED OFF AND ALLOWED TO COOL.

HOT EQUIPMENT CAN CAUSE BURNS.

CAUTION: USE STEP LADDER OR OTHER STABLE PLATFORM TO PROVIDE EASY

ACCESS TO THE INTERIOR OR THE UVC LAMP CABINET. DO NOT STAND ON

COOKING EQUIPMENT TO SERVICE THE UVC. FALLS CAN CAUSE SERIOUS

INJURIES.

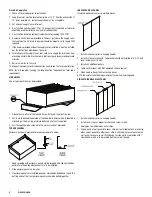

BAFFLE FILTERS

Filters should be removed and cleaned at least weekly, depending on hours of

operation. Filters may be cleaned by soaking in a strong detergent solution or

running thru a dishwasher. When replacing, make sure filters and handles are

running vertically, and filters are seated properly.

MODULAR GREASE EXTRACTORS

Modules should be removed and cleaned at least weekly, depending on hours of

operation. Modules may be cleaned with a brush and a strong detergent solution

or run thru the dishwasher. When replacing modules, make sure they are seated

properly.

GREASE TROUGH

Should be checked weekly for grease build up and cleaned with strong detergent

if necessary.

GREASE COLLECTION RECEPTACLE

Should be emptied at least once a day and cleaned daily with a strong detergent.

HOOD CANOPY

Inside hood canopy should be wiped down as needed. The area at the exhaust

intake openings should be wiped down daily.

Inspect inside of extraction chamber at least weekly to insure proper cleaning

and that the trough and access door are free of foreign matter.

UV PREVENTATIVE MAINTENANCE

Clean the UV lamp at the same time the grease extractors are being cleaned (or

daily), wipe down the UV lamp exterior using a dry towel and a non-detergent

cleaning agent such as sanitizing solution or white vinegar.

IMPORTANT: Do not allow cleaner to run into lamp fittings or socket enclosures.

IMPORTANT: UV System will not work properly without daily cleaning of the UV

lamp.