5

OM-DH(T) DOMESTIC & (CE) INTERNATIONAL

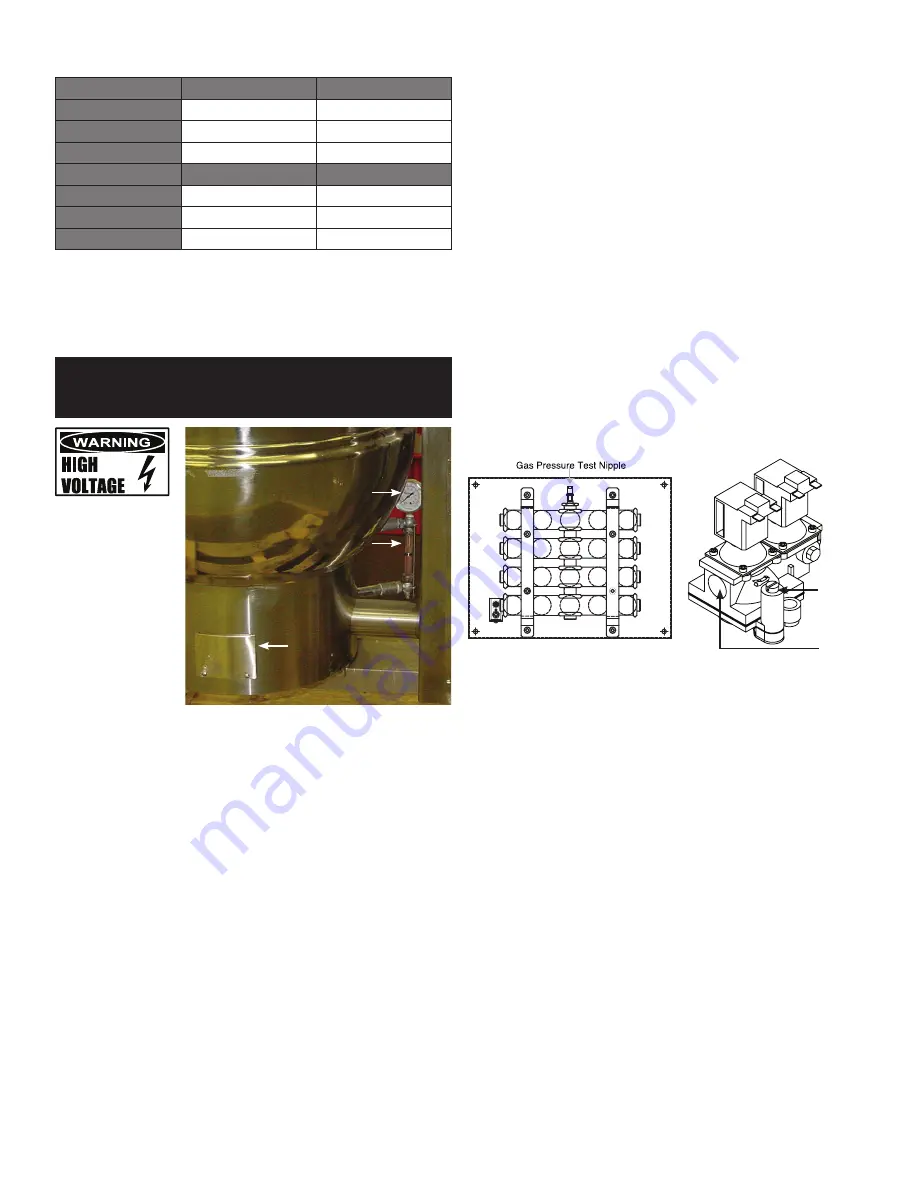

A pressure test point is fitted on the burner manifold and on the gas control valve.

Natural (G20) Models

mBar

WCI (Water Column Inches)

DH-20

8.75

3.5

DH/1-40

8.75

3.5

DH-60

8.75

3.5

Propane (G31) Models

mBar

WCI (Water Column Inches)

DH-20

25

10.0

DH/1-40

25

10.0

DH-60

25

10.0

BURNER ADJUSTMENT

The burners are fixed aeration type and have no provision for adjustment of air inlet.

INITIAL START-UP

CAUTION: ENSURE THAT THE KETTLE CONTAINS LIQUID WHEN THE BURNERS ARE

ALIGHT.

WARNING: THIS APPLIANCE MUST BE EARTHED.

Water Level

Gauge &

Sight Glass

Pressure

Gauge

Gas Valve

Access Cover

GAS SUPPLY

Connect the unit to the gas supply and test for gas soundness. For gas supply

down stream of the gas valve, leak detection spray or soap solution may be used

with the burners lit.

ELECTRICAL SUPPLY

Before commissioning the appliance, ensure that the electrical installation has

been carried out to the relevant regulations (see Installation section).

JACKET WATER LEVEL/JACKET PRESSURE

Ensure the water level in the jacket is correct, by confirming that it is between

the sight glass marks. If it is low, follow instructions in Servicing and Conversion

section, Jacket Filling.

Check the pressure gauge. If it does not show 20 or more inches of vacuum (that

is, a reading of 20 to 30 below zero) see Servicing and Conversion section, Jacket

Vacuum.

PRE-COMMISSIONING CHECK

1. Prior to operation, clean out kettle thoroughly using hot water and detergent.

Rinse kettle thoroughly.

2. Remove all literature and packing materials from the interior and exterior of

the unit.

3. Ensure the open end or the elbow at the outlet of the safety valve is directed

down. If not, turn the elbow to the correct position. See detailed Instructions in

Servicing and Conversion section for Safety Valve installation and operation.

START-UP

Now that your kettle has been installed, you should test it to ensure that the unit

is operating correctly.

1. Remove literature and packing materials from the interior and exterior of the unit.

2. Put a small amount of water into the kettle (6 to 13 mm). With the kettle in the

horizontal position, note how the water lies in the kettle, to confirm that the

pan was leveled properly during installation.

3. Following the “To Start Pan” instructions for your kettle model, begin heating

the water at a temperature setting of 235ºF (113ºC). At this setting, heating

should continue until the water boils.

4. To shut down the unit, switch the power switch to OFF.

5. Turn the tilting handwheel counterclockwise to pour out the water and to

confirm that the kettle body can be tilted smoothly from horizontal to vertical.

If the unit functions as described above, it is ready for use. If it does not, contact

your local Authorized Service Agency (Domestic) or Engineer (CE).

After installing and commissioning the appliance, the user’s instructions should be

handed to the user or purchaser. Ensure that the instructions for lighting, turning

off, correct use and cleaning are properly understood. The location of the main gas

isolating valve should be emphasized and the emergency shut down procedure

should be demonstrated.

SETTING THE GAS PRESSURE

Capscrew

for Governor

Pressure

Adjustment

Gas Inlet

1. It is necessary to check the gas pressure during commissioning. A pressure

gauge must be connected to the pressure test point on the gas manifold. See

above figure for test points.

2. Turn the main gas and electricity supply on.

3. Light the burners.

4. Remove cover plate on the round skirt at bottom of kettle.

5. Remove governor cap screw from control valve. See above figure for position

on valve.

6. Governor adjustment is suitable for both natural and propane gas.

7. To increase pressure turn the screw inside the governor turret clockwise;

anti-clockwise to reduce pressure. Check the burner pressure again after 15

minutes operation and adjust if necessary.

8. Disconnect the pressure gauge from the test point. Re-seal the pressure test

point and test for gas soundness.

9. Replace governor cap screw and replace cover plate.

CHECKING PERFORMANCE OF CONTROLS

1. Light the unit. Check that controls quickly and smoothly produce a healthy

spark from the electrode to the earthing post.

2. Turn controller off and then on. Check that burners go out and reignite smoothly

and quickly when switched back on. Repeat several times.

3. If the unit fails to respond as described, it should be serviced by an authorized

Groen service agent.

Summary of Contents for unified brands groen DH-20

Page 16: ...16 OM DH T DOMESTIC CE INTERNATIONAL Parts List GAS VALVE PIPING BOTTOM COMPONENTS ...

Page 27: ...27 OM DH T DOMESTIC CE INTERNATIONAL Wiring Diagram Domestic For Classic Control Models ...

Page 28: ...28 OM DH T DOMESTIC CE INTERNATIONAL Wiring Diagram Domestic For Advanced Control Models ...

Page 29: ...29 OM DH T DOMESTIC CE INTERNATIONAL Wiring Diagram CE ...