DV425TR DIRECT VENT ROOM HEATER

02/01 Page 14 250-5533

LP CONVERSION, CONT.

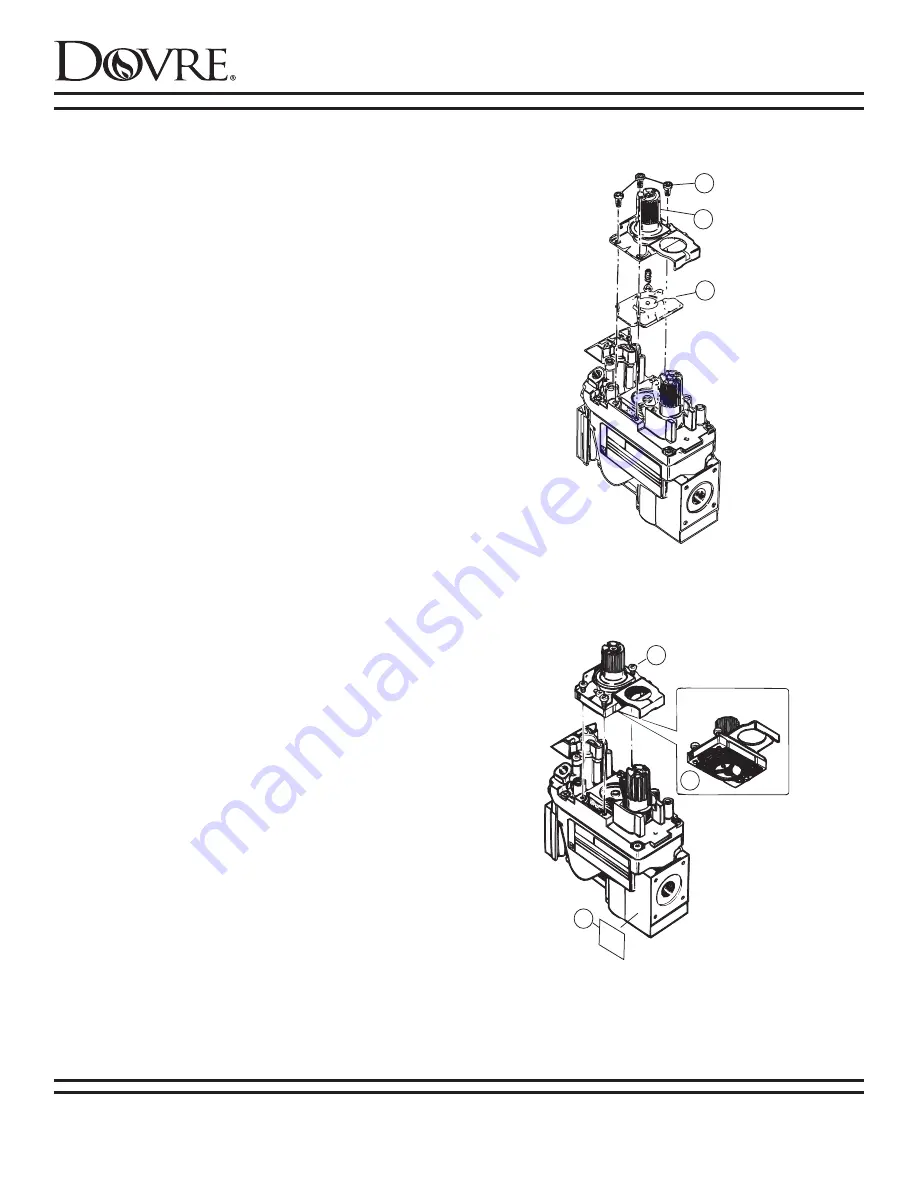

Valve Regulator Replacement

1. Turn control knob to the OFF position, ensure that gas

supply to the valve has been turned off.

2. Using a Torx TH20, or slotted screwdriver, remove the

three pressure regulator mounting screws (A), pressure

regulator tower (B), and diaphragm (C). (You may wish

to retain these items for converting back to original gas

if necessary.)

3. Ensure that the rubber gasket (D) is properly positioned

and install the new HI/LO pressure regulator assembly

to the valve using the new screws (E) supplied with

the kit. Tighten screws securely. (Reference torque

= 25 in/lb)

4. Install the enclosed identification label (F) to the valve

body where it can be seen.

5.

Re-install burner plate: First slide burner tube into shut-

ter and over holes. Secure plate with screws.

6.

Re-install log/burner pan. Slide vertically into the back

of firebox and then place horizontal onto burner plate.

Refer to Fig. 1 again.

7.

Install logs, refer to Owner's Manual for correct place-

ment.

8.

Replace glass door and front.

A

B

C

E

D

F