DPtech LSW5003 Series Industrial Ethernet Switch Installation Manual

Chapter 2Installation

15

Table2-1

Temperature/humidity requirement

Temperature

Relative humidity

-40

℃~

70

℃

0%

~

95% (non-condensation)

2.2.2 Cleanliness

Dust is a hazard to the operating safety of your device. The dust accumulated on the chassis can cause

electrostatic adsorption, one of the sources that cause the poor contact of connectors or metal contact

points. This not only shortens the service life of your device but also causes communications failures.

When the indoor relative humidity is low, electrostatic adsorption is more likely to happen.

The equipment room must be free of explosion hazards and the electric and magnetic conductible dust

as well. The contents of the dust must be limited to the values shown in Table 2-2.

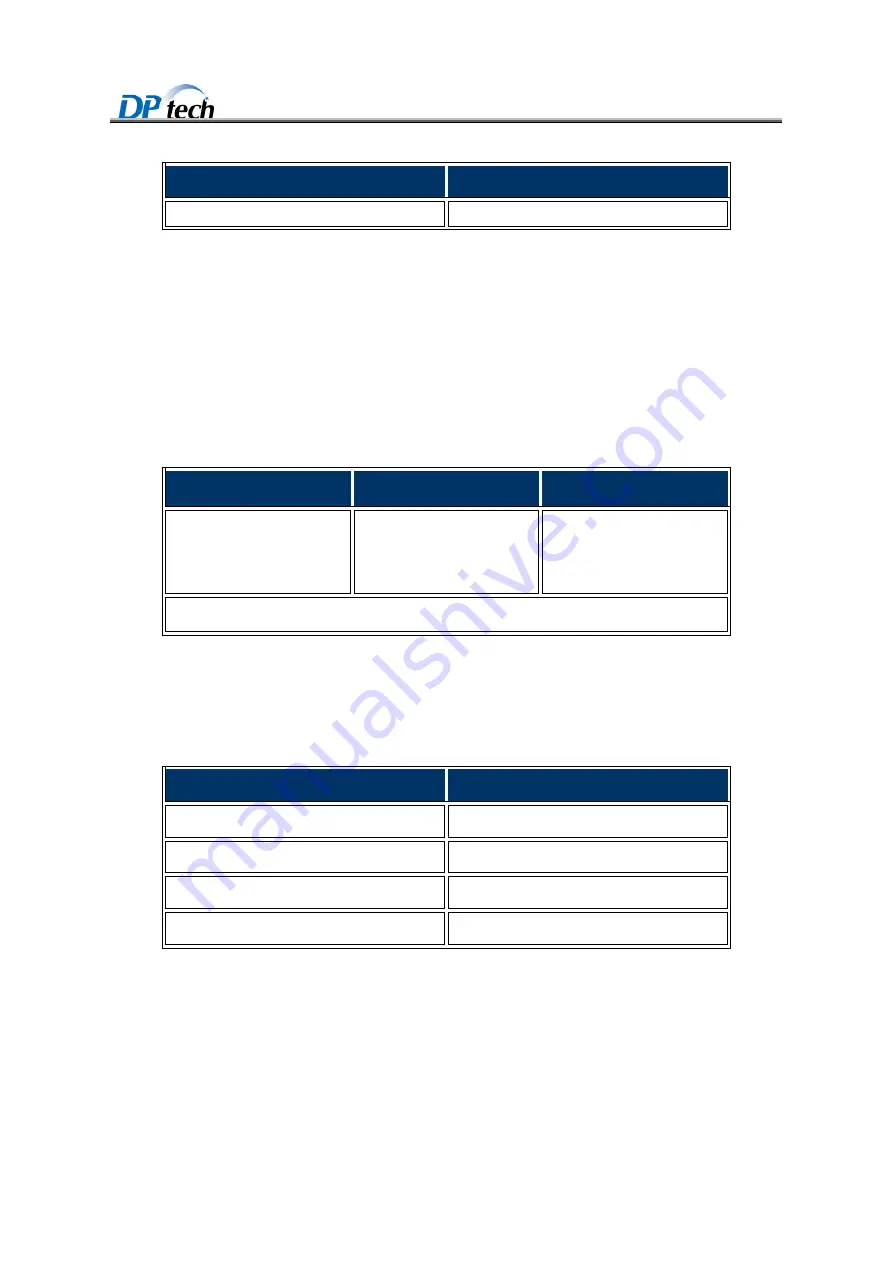

Table2-2

Dust limit in the equipment room

Substance

Unit

Content

Dust

Particles/m

³

≤

3

×

10

4

(No visible dust on the

table top for three days)

Note: Diameter of a dust particle

≥

5

μ

m

Besides the dust, there are rigorous limits on the harmful gases that can accelerate the erosion and

aging of metals, such as salts, acids, and sulfides. Equipment room should prevent from harmful gases

such as SO

2

、

H

2

S

、

NH

3

、

Cl

2,

as shown in Table2-3

错误

!

未找到引用源。

.

Table2-3

Limit of harmful gases in the equipment room

Gas

Maximum (mg/m3)

SO

2

0.2

H

2

S

0.006

NH

3

0.05

Cl

2

0.01

2.2.3 ESD requirement

Although the switch is designed to be electrostatic discharge (ESD) preventive, the card circuits and

even the device can be badly damaged when excessive static electricity is present. To get much better

ESD effect, you should:

Connect your device to the earth ground properly.