CONTACT US AT

www.DRpower.com

15

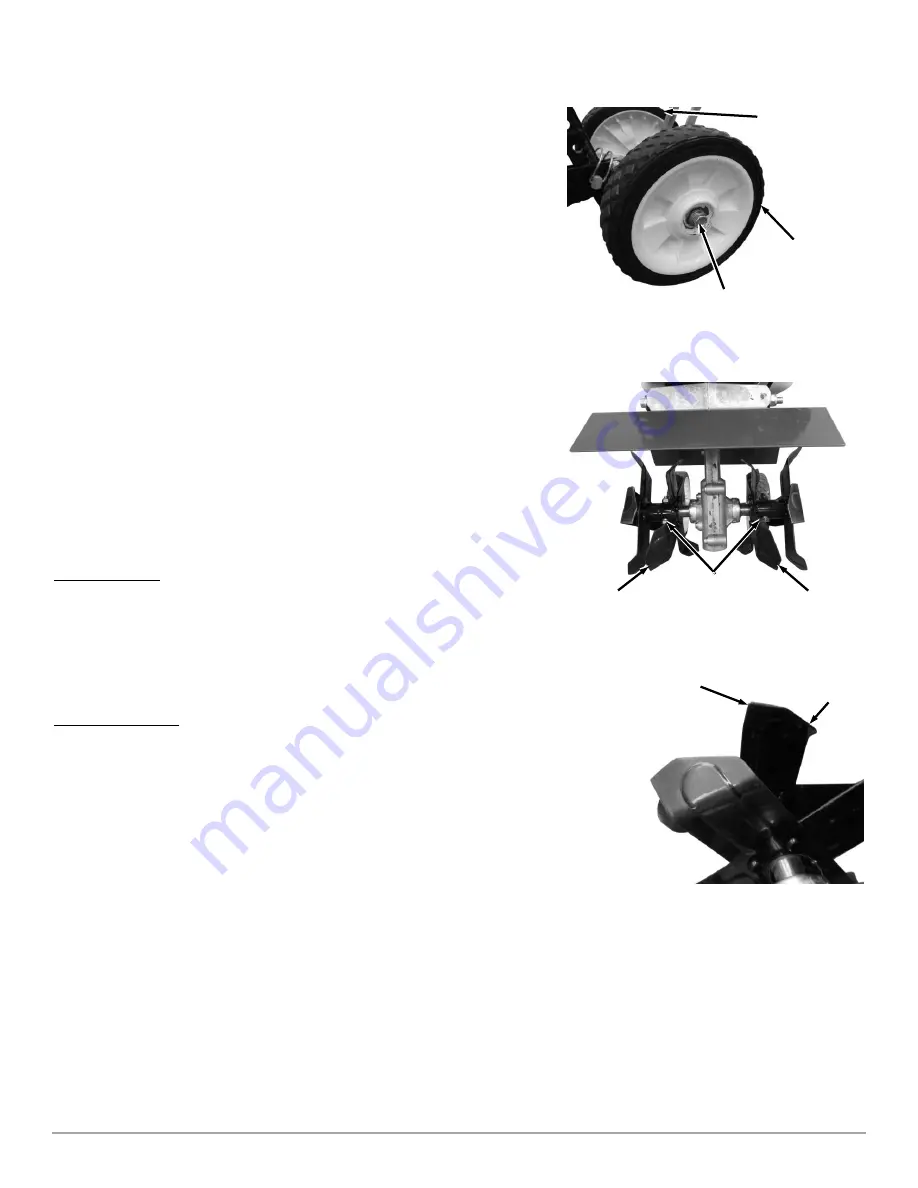

Replacing Wheels

Tools Recommended:

Two 14mm Wrenches

1.

Hold the Axle Bolt securing the left side Wheel using a 14mm Wrench and

remove the Locknut and Washer on the right side using a 14mm Wrench

(Figure 15).

2.

Tilt the machine to the left side to remove the right side Wheel. Tilt the

machine to the right side to remove the Axle Bolt, Washer, and left side

Wheel.

Note: Ensure the Spring and Washer are in position on the Wheel Shaft when

installing the left side Wheel and Axle Bolt. The Washer must be positioned

between the Spring and Wheel. On page 18, see explode drawing items 47

and 48 for reference to position the Spring and Washer correctly.

3.

Install the new Wheels in the reverse order and tighten the Axle Bolt and

Locknut.

Tine Remove and Replace

Tools and Supplies Recommended:

Two 13mm Wrenches

Note: For ease of disassembly and assembly, block up the machine so that the Tines

are off the ground.

Tine Removal:

1.

Remove the Bolt and Locknut that secures the right side Tine Assembly to

the Shaft using two 13mm Wrenches (Figure 16).

2.

Remove the Bolt and Locknut that secures the left side Tine Assembly to the

Shaft using two 13mm Wrenches.

3.

Slide the Tine Assemblies off the Shaft.

Tine Installation:

1.

Install the left side Tine Assembly onto the Shaft with the squared edge

facing forward the angled Tine edge facing back (Figure 17).

2.

Align the holes of the left side Tine Assembly with the Shafts and secure it

with the Bolt and Locknut using two 12mm Wrenches.

3.

Install the right side Tine Assembly onto the Shaft with the squared Tine

edge facing forward the angled Tine edge facing back.

4.

Align the holes of the right side Tine Assembly with the Shafts and secure it

with the Bolt and Locknut using two 12mm Wrenches.

Note: It is important the Tine Assemblies are installed on the correct right and left

sides to work properly. The square Tine edges face forward and the angled

Tine edges face back.

Square

Edge

Figure 17

Angled

Edge

Bolt and

Locknut

Figure 16

Left Hand Tine

Assembly

Right Hand Tine

Assembly

Left Side

Wheel

Figure 15

Axle Bolt

with Washer

Right Side Wheel

with Locknut and

Washer