SECTION IV - CHIPPING

1. To process branches, dry or green feed into the chipper hopper. It is best to clip off side twigs or limbs from

the main branch. Enter one branch at a time if they are 2” or more in diameter. Green branches process

quicker and easier then dry branches and soft wood is easier than hardwood. Push the branch in at the angle

of the hopper and throat. Always have the removable hopper in place. Never allow your hands to enter the

hopper. As the chip branch shortens, finish chipping it by shoving the stub down the chipper tube with the next

branch to be chipped.

2. When chipping branches, sometimes a tail will be left at the end of the branch (usually green wood), which will

increase in length as you chip and eventually rap around the shaft or bearings. To avoid this we recommend

twisting the branch as you feed it into the chute. This will also improve the chipping performance.

Use common sense when using your chipper. Learn to recognize the change in sound when it is overloaded. If

the machine becomes jammed by overloading or another cause, stop the engine immediately and no damage will

occur. IF YOU JAM THE UNIT AND DO NOT STOP THE ENGINE, IT WILL BURN THE BELT OR RUIN THE

CLUTCH. To free a jammed flywheel, stop the engine, remove

both

spark plug wires and remove the material left

in the chipping chamber. It may be necessary to remove the deflector cover (item #1, pg. 17) to allow easier

cleaning of the machine. Make sure to replace deflector cover with all supplied hardware to reduce risk of injury.

Check to see that the flywheel will turn freely before you start the chipper. Only your operator experience will tell

you how fast to feed limbs.

WARNING: Do not allow chips to build up within 3” of

discharge chute opening. Move chipper or pile as needed.

Failure to do this could result in unnecessary jamming of

machine.

To move pile, use spade, rake, or long handle tool.....

NEVER USE YOUR HANDS OR FEET!!!

1. Never allow your hands or any part of your body or clothing inside the feed hopper or discharge area of the

chipper. Use a wood stick to push material down the hopper.

2. Keep all protective guards on the machine and deflectors in place and in good working condition.

3. Always stand clear of the discharge area when the chipper is running.

4. Keep your face and body back from the feed hopper to avoid being struck by any material that may bounce

back. Do not overreach, keep proper balance and footing.

5. Do not transport the chipper while the engine is running.

6. Do not refuel the engine while it is hot, warm, or running.

7. Do not cover the chipper while the muffler is still hot.

Summary of Contents for 18.0 HP

Page 2: ...2...

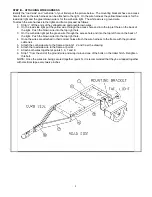

Page 18: ...18 PARTS BREAKDOWN C182 CHP CHIPPER...

Page 20: ...20 PARTS BREAKDOWN 913 0215 CHIPPER BASIC MACHINE...