14

INSTRUCTIONS FOR ADJUSTING OR REPLACING BELT

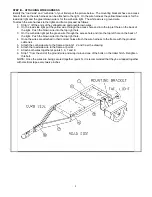

If the belt needs replacing or tightening, follow these instructions carefully.

1. Remove the belt guard (item #27, pg.17).

2. Check alignment of the clutch (item #20, pg. 17) with drive pulley (item #18, pg. 17) by placing a straight-edge

across both faces (see figure 1). If adjustment is necessary, adjust rotor pulley.

DO NOT ADJUST BY

MOVING CLUTCH ON ENGINE SHAFT.

3. Loosen engine bolts and nuts (items #50 & #51, pg. 17).

4. Install the drive belt (item #21, pg. 17) and tighten belt tensioner (item #30, pg. 17) until belt deflection is as

shown in figure 2.

5. Tighten engine mounting bolts and nuts securely.

6. Re-install the belt guard before operating your unit.

Figure 1

NOTE

: Check and re-tighten belt after

break-in period.

TROUBLESHOOTING

Symptom Problem

Correction

Clutch overheats.

Belt burns.

Flywheel won’t turn.

Clutch is slipping or flywheel is

jammed or stopped.

A. Immediately stop engine.

B. Remove spark plug wire.

C. Turn flywheel by hand to be sure it

turns freely.

D. Check belt tension.

Chipping action seems too slow or

flywheel stalling.

Engine speed is too slow.

Belts are slipping.

Run engine at full throttle.

Check for loose or missing belt &

tighten.

When chipping, log seems to

vibrate excessively & “hammers”

hands.

Knives are dull.

Gap between knife & wear plate is

too great.

Remove knife & sharpen - be sure to

maintain same bevel of 45 degrees.

Adjust gap as per instructions.

Chipper knives move over and are

striking chipper side plate.

Taper lock bushing is loose.

Set screws in flywheel shaft bearings

are loose or missing.

If key in taper lock bearing is too deep,

file key to seat properly. Reset the

proper knife gap & tighten set screws.

Engine runs but flywheel doesn’t

rotate.

Inner shoes of clutch worn.

Retaining springs weak or broken.

Loose drive belt.

Replace worn or broken clutch parts.

Check belt tension.

Clear chipper chamber.

Figure 2

Summary of Contents for 18.0 HP

Page 2: ...2...

Page 18: ...18 PARTS BREAKDOWN C182 CHP CHIPPER...

Page 20: ...20 PARTS BREAKDOWN 913 0215 CHIPPER BASIC MACHINE...