contact us at

www.DRpower.com

13

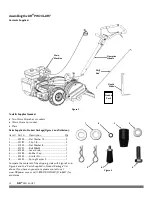

Operation Handle

1.

The M8×75 bolts and nuts have been fixed in the guide

bracket for shipping. First, remove the M8x75 bolts and

nuts from the guide bracket.

2.

Align the holes in the operation handle shaft with the

holes in the guide bracket and re-insert the M8x75 bolts

and screw nuts to tighten. (See Figure 5)

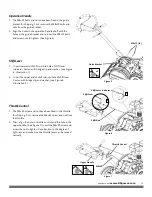

Shift Lever

1.

Insert lower end of shift rod into hole of shift lever

indicator. Fasten with bridge clip and washer. (see Figure

6, Illustration 1)

2.

Insert the upper end of shift rod into hole of shift lever.

Fasten with bridge clip and washer. (see Figure 6,

Illustration 2)

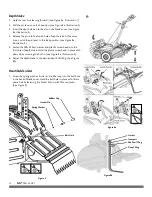

Throttle Control

1.

The M6×50 screw and nut have been fixed in the throttle

for shipping. First, remove the M6×50 screw and nut from

the throttle.

2.

Then, align the hole in throttle control and the hole in the

upper handle. (See Figure 7) Insert the M6×50 screw and

screw the nut to tighten. Pay attention to the degree of

tightness, and make sure the throttle lever can be moved

normally.

M8x75 (x2)

Guide Bracket

x2

Figure 5

Figure 6

1

Shift Lever Indicator

Shift Lever

2

Shift Rod

M6x50

Figure 7

Throttle Control

Upper Handle