Operating Instructions

1.

This Power Tool is intended for industrial applications, for cutting

sheet metal max. capacity is indicated in the technical data. Do

not cut sheet metal through, or along welding points, or multi

layer sheets, which exceed the max. cutting capacity.

To cut

spiral wound tubing 4 x 0.9 mm in metal , the model 3514-2 or

3514 -7R must be used.

To Switch ON: Slide the switch (82) forward

To Switch OFF: Slide the switch (82) to the rear.

2.

The shear must always be guided flat and the best cutting result

is achieved, when the jaws pos. 10 are positioned flat on top of

the material, also when cutting circular cuts.

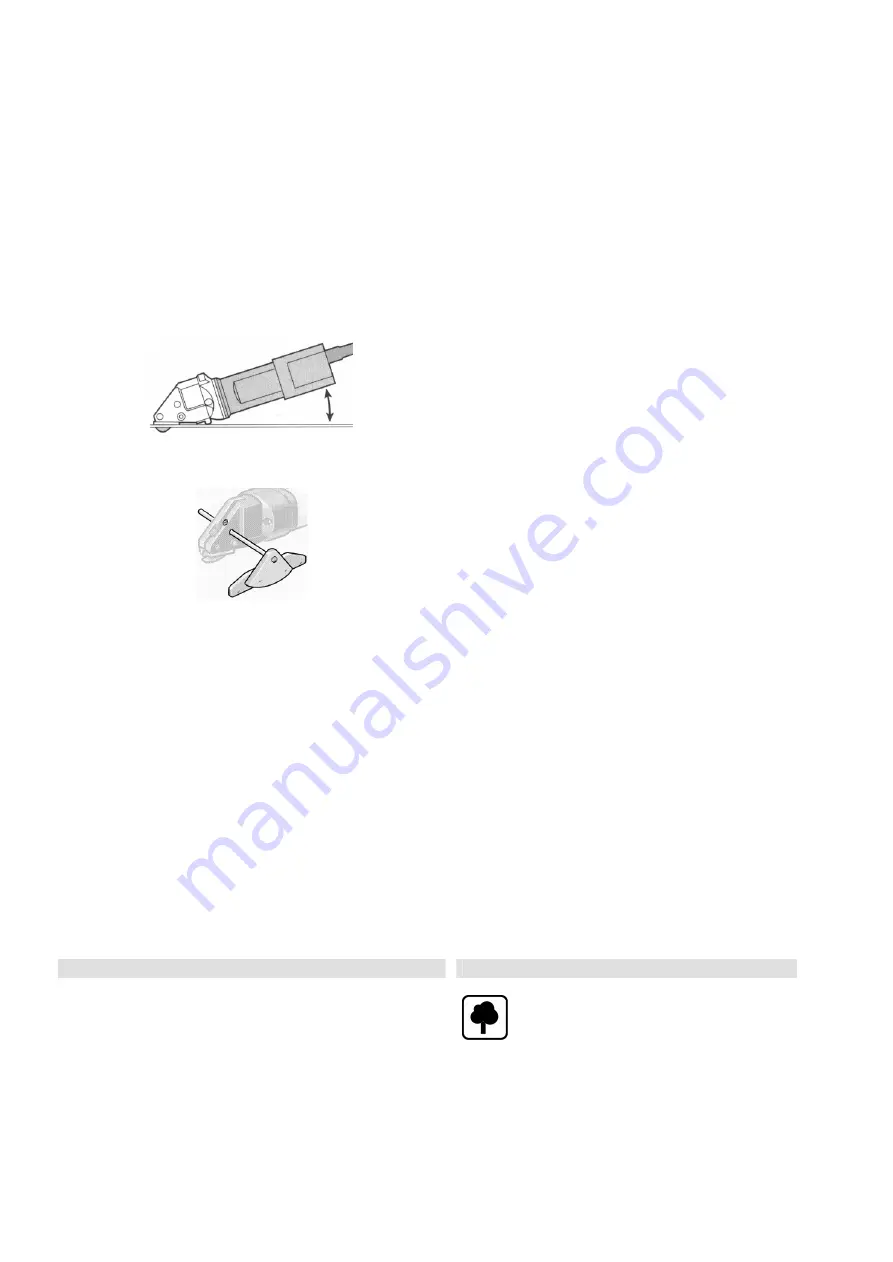

Adj ustable guide S/01

3.

When stopping inside the material, pull metal shear back

straight out of the waste, with motor in operation. If too

long cut waste off, first.

4.

Circular cuts, always cut anti clockwise from right to left.

The outside radius is unlimited.

5.

For cutting out curved or inside patterns a 12 -14 mm

hole must be drilled or punched or a slot should be

made to insert the cutting knife. Square or rectangle cut-

outs, drill in each corner a hole between 12 -14 mm.

6.

A one side cut with the metal shear is possible, a small

strip can be easily cut off without leaving a burr and any

distortion or scratch marks.

7.

Cutting the same parts, a template can be

manufactured. Without risk of damaging the knife, a cut

along the template is possible. Front points of the jaws

left and right are us ed to cut exact along a marked line.

To cut strips, use adjustable guide S/01. This guide is

infinitely variable, due to the hole in the housing and can

be tightened with the set screw. Adjustable guide S/01

can be delivered in 100, 250 and in 500 mm length.

8.

Knife and jaws can be sharpened. After being

sharpened or replaced, the knife at it’s lowest point,

should protrude the jaws by about 2.5 mm. The gap

between the knife and the jaws should be approximately

0.1 mm on both sides. For a burr free cutting adjust the

cutting gap as follow: Loosen screw, adjust the gap with

set screw, to the left narrow, to the right wide, and

tighten screw again. Check gap with a feeler gauge.

9.

If you read these suggestions carefully, any kind of

material can be cut about 200 working hours, before

sharpening knife and jaws.

10. The material to be cut, must always be free of oil or

grease.

Care and Maintenance

Guarantee

Before repairing or any maintenance on machine, disconnect from

power supply by removing plug fro m socket.

Always keep the machine and the ventilation slots clean.

Oil the knife pin

18

and knife

11

at regular intervals.

If the machine should happen to fail, despite the care taken in

manufacture and testing, repair should be carried out by an authorised

customer services agent for Dräco power tools.

Dräc o tolls carry a guarantee of 24 months from date of

delivery.

Damage attributable to normal wear and tear, overload or

improper handling will be excluded from the guarantee.

In case of complaint pleas e send the machine,

undismantled

, to your dealer or the Dräco Service Centre for

electric power tools.

Declaration of conformity

Environmental protection

We declare under our sole responsibility that this product is in

conformity with the following standards.

EG 98/37 EG, EG 73/ 23 EG, EG 89/336 EG, or standardisation

documents EN 292 part I, EN 292 part II, EN 50 144, EN 55 014,

EN 60 555, HD 400, HD 400.3 part II/H

02 Max Draenert

Recycling raw materials instead of waste

disposal

Machine, accessories and packaging should be sorted for

environment-friendly recycling.

These instructions are printed on recycling paper

manufactured without chlorine.