NMGS

PMC PROCEDURE (continued)

6-19

6.8.5.9

Remove all test equipment.

6.8.6

PEEP Valve w/Bypass - If applicable

6.8.6.1

Open the APL valve.

6.8.6.2

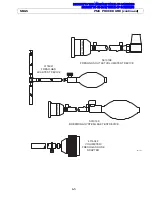

Interconnect the inspiratory valve and expiratory valve or

expiratory port on the ultrasonic flow sensor, if applicable

with a 22 mm hose (P/N 9995132).

6.8.6.3

Attach a Breathing System Leak Test Adapter (P/N S010159)

to the bag mount.

6.8.6.4

Disconnect the pressure pilot line from the absorber and

replace it with a PDM To Monitor Adapter (P/N 4115041).

6.8.6.5

Connect a test gauge to the adapter.

6.8.6.6

Set the O

2

flow to 5 l/min.

6.8.6.7

*

Place the PEEP bypass in the ON position.

6.8.6.8

Adjust the absorber PEEP valve clockwise to the maximum

position.

6.8.6.9

Does the PEEP valve adjust smoothly? ___ (Y)

6.8.6.10

Is the maximum PEEP indicated on the test gauge within 15

to 22 cm H

2

O? ___ (Y)

6.8.6.11

*

Place the PEEP bypass in the OFF position.

6.8.6.12

*

Does the PEEP return to < 3 cm H

2

O? ___(Y)

6.8.6.13

Adjust the absorber PEEP valve counterclockwise to its

minimum position.

6.8.6.14

Does the PEEP return to < 3 cm H

2

O? ___(Y)

6.8.6.15

Close the O

2

flow control valve.

6.8.6.16

Remove the test equipment and reconnect the pilot line to the

absorber.

*

These items apply only to machines with a PEEP by-pass.

6.8.7

Bain Circuit Adapter - If applicable

6.8.7.1

Close the Bain Circuit APL valve by turning the knob fully

clockwise.

6.8.7.2

Verify the cm H

2

O gauge at zero (0) and readjust if necessary.

NOTE:

The small slotted screw is the zero adjust.

6.8.7.3

Insert the O

2

sensor plug into the O

2

sensor inlet on the Bain

Circuit.

6.8.7.4

Attach a Breathing System Leak Device (P/N S010159) to the

Breathing Bag port on the Bain Circuit.

(

9

)

Summary of Contents for Narkomed GS

Page 2: ...RETURN TO CD ROM TABLE OF CONTENTS RETURN TO THIS MANUAL S TABLE OF CONTENTS ...

Page 10: ...RETURN TO CD ROM TABLE OF CONTENTS RETURN TO THIS MANUAL S TABLE OF CONTENTS ...

Page 40: ...RETURN TO CD ROM TABLE OF CONTENTS RETURN TO THIS MANUAL S TABLE OF CONTENTS ...

Page 46: ...RETURN TO CD ROM TABLE OF CONTENTS RETURN TO THIS MANUAL S TABLE OF CONTENTS ...

Page 50: ...RETURN TO CD ROM TABLE OF CONTENTS RETURN TO THIS MANUAL S TABLE OF CONTENTS ...

Page 52: ...RETURN TO CD ROM TABLE OF CONTENTS RETURN TO THIS MANUAL S TABLE OF CONTENTS ...

Page 90: ...RETURN TO CD ROM TABLE OF CONTENTS RETURN TO THIS MANUAL S TABLE OF CONTENTS ...

Page 91: ...RETURN TO CD ROM TABLE OF CONTENTS RETURN TO THIS MANUAL S TABLE OF CONTENTS ...