Issue 6 – December 2006

25

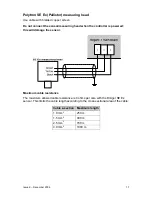

Calibrating an SE Ex unit

Use the controls on the pellistor board to set sensor current, calibrate zero and

calibrate span:

(Also refer to the measuring head’s operating manual for calibration instructions.)

Set the sensor current

1. Set the sensor drive current range with SW1-A on the pellistor board.

For all Dräger sensors, set SW1-A to

OFF

.

SW1

Drive current

range

A

B

C

D

95 – 195 mA

ON

–

–

–

190 – 350 mA

OFF

– – –

The position of switches B, C and D does not matter yet.

2. Adjust the sensor current to the required value

x

Turn off the unit by disconnecting the AC or DC supply and batteries, if fitted

x

Connect an ammeter between terminal 9 and the sensor

x

Re-connect the AC or DC supply

x

Adjust VR2 on the pellistor board to set the current (270.0 mA for Dräger Ex

sensors). Allow two minutes for the current to settle after adjusting VR2. Re-

adjust VR2 if necessary

x

Disconnect power, remove the ammeter and reconnect the sensor

x

Turn on power and allow sensor to settle or at least five minutes before

continuing with zero and calibration

SW1

VR3

VR1

VR2

Summary of Contents for REGARD-1

Page 38: ...Issue 6 December 2006 38 EC type examination certificate ...

Page 39: ...Issue 6 December 2006 39 ...

Page 40: ...Issue 6 December 2006 40 ...

Page 41: ...Issue 6 December 2006 41 ...

Page 44: ...Issue 6 December 2006 44 ...

Page 46: ...Issue 6 December 2006 46 ...

Page 47: ...Issue 6 December 2006 47 ...