中龙集团

Dragon Group China Limited

BIRD

®

h. Program configuration notes

Basic parameters: Sn, Ctrl, OP1, OP2

Sn, Ctrl, OP1, OP2 are the basic four parameters. They have great impact on other

parameters. Therefore, we should set these four basic parameters first, according to the

specific requirements.

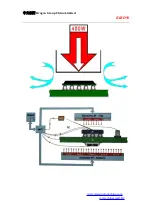

Output parameters: OP1, OP2, Hct.Cct

When setting OP1 and OP2, be sure to choose the right output module. If the output

module is a relay, logic level module or SCR zero module, then OP1 should be set at

Time proportion output. If we choose circuit output module, the OP1 should be set at

4-20mA or 4-20mA output.

When we choose time proportion output, we should set Hc,t.cc,t. If we choose

SSR(solid-state relay) or SCR zero module, the action period can be set at 2s; if we

choose relay to output, the action period should be no less than 20s.

Regulation parameter: ProP.ln

と

,

と

,dEr,

と

,rEL.C

ProP, ln

とと

,dEr

と

, rEL.C are the four regulation parameters, directly affecting

control precision.

Only if the system is heating or cooling, rEL.C displays.

In the process of PID self-setting, the system can only set ProP, ln

とと

and dEr

と

.

The cooling parameter rEL.C should be set by hand.

If the adjust method is set at positioning adjustment, ProP is the difference of positioning

adjustment.

When Pbd is set at C-F, the unit of ProP is Celsius or Fahrenheit; when Pbd is set at Pct,

the unit of ProP is %, and then the heating area equals ProP multiplied by the heating

proportion coefficient PH-L. The greater the cooling coefficient, the greater the cooling

output power. The cooling output power equals the temperature difference divided by

heating proportion,then mutiplied by cooling coefficient.

Control mode parameter Rc

と

When Rc

と

is set at rEu, the control mode is reverse-acting control. It means that as

the input signal of the meter increases, the adjustment output decreases. For example, in

heating control system, when the temperature rises, the output heating power should

decrease, so we choose reverse-acting control.

When Rc

と

is set at rEu, the control mode is positive-acting control. It means that

as the input signal of the meter increases, the adjustment output increases. For example,

in heating control system, when the temperature rises, the output heating power should

increase, so we choose positive-acting control.

Summary of Contents for Bird AC-5K

Page 18: ...Dragon Group China Limited BIRD www dragongroupchina com www chinaemall biz...

Page 19: ...Dragon Group China Limited BIRD www dragongroupchina com www chinaemall biz...

Page 26: ...Dragon Group China Limited BIRD www dragongroupchina com www chinaemall biz...

Page 31: ...Dragon Group China Limited BIRD www dragongroupchina com www chinaemall biz...