中龙集团

Dragon Group China Limited

BIRD

®

H. Related information

1. How to deal with the Voids produced by the lead BGA in lead-free

soldering?

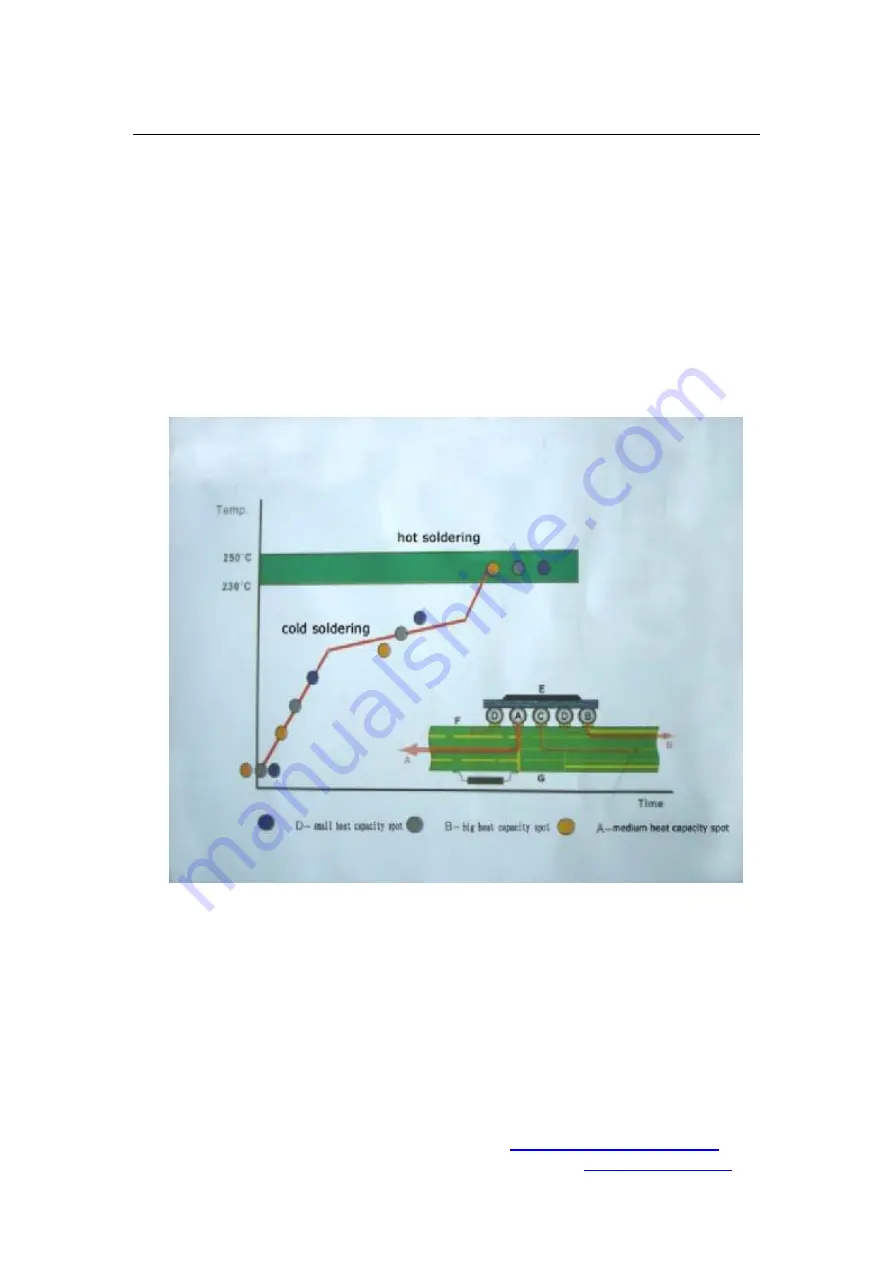

As the development of the lead-free technology, more and more SMT processing

enterprises come across the problem of Voids in production.

Many companies try to avoid using lead BGA in lead-free soldering technology.

Because the melting point of lead soldering balls is lower than lead-free tin paste. The tin

balls melt first and surround the tin paste, so that the flux in the paste can't volatilize, and

form bubbles inside. If there is via on the soldering pad, there may be more bubbles.

Steps of desoldering and replacing BGA/CSP with lead-free desoldering materials:

Set the temperature curve;

Desoldering the broken parts;

Clean and preparation for the repair work;

Remount the reworked parts with flux paste.

Detection of reflow soldering.

a

. Requirement of devices in reworking

Repairing method of BGA/CSP is convection, not radiation, so soldering iron is not

the ideal choice. In normal reworking of BGA, it is difficult to use IR, because the

Summary of Contents for Bird AC-5K

Page 18: ...Dragon Group China Limited BIRD www dragongroupchina com www chinaemall biz...

Page 19: ...Dragon Group China Limited BIRD www dragongroupchina com www chinaemall biz...

Page 26: ...Dragon Group China Limited BIRD www dragongroupchina com www chinaemall biz...

Page 31: ...Dragon Group China Limited BIRD www dragongroupchina com www chinaemall biz...