25

24

MODE/TIMER

ON/OFF

MAINTENANCE

1

2

FLUSHING TIME

TEMPS DE VIDANGE

1. Tenir 6 sec. pour réinitialiser.

2. Pesez 1 fois pour vidange court.

Pesez 2 fois pour vidange moyen.

Pesez 3 fois pour vidange long.

1. Hold 6 sec. to reset.

2. Hit once for short flushing time.

Hit twice for medium flushing time.

Hit 3 times for long flushing time.

As illustrated on pages 6 and 7 of this manual, the Automatik system evacuates wastewater automatically

after approximately 10 to 15 minutes. Keep in mind that as long as the system is operating, water keeps

flowing and the unit eventually fills up. The membrane allows you to adjust the time lapse during which the

unit deactivates and empty its contents. The unit also clears out the wastewater once the unit stops.

WHY CHANGE THIS PARAMETER?

• With the decanter configuration, the unit can reactivate as soon as there is no wastewater left to flow

through the rubber hand (in other words when all the wastewater is in the separate funnel).

• If the unit’s drain is located very close to the pipe leading to the sewer and that there is less restriction

to the amount of wastewater that can be evacuated, the evacuation time could be set on medium.

• On the other hand, if the diameter of the pipe leading to the sewer is smaller and restrains the

amount of water that can be evacuated, increasing the evacuation time to a long flushing time could

be necessary.

ON/OFF

The first LED will stay lit if the unit is on. Press

once to turn it off. It will then start flashing,

indicating that power is still running through

the system, even though the unit is turned off.

MAINTENANCE

The middle LED will light up after 500 hours of

usage. This means maintenance is required and

the unit should be taken to a Drainvac retailer

to be examined. Maintenance should only be

reset by a qualified Drainvac technician.

FLUSHING TIME

• Press once to initiate short flushing time - LED will flash once.

• Press twice to initiate medium flushing time - LED will flash twice.

• Press three times to initiate long flushing time - LED will flash three times.

HOW THE MEMBRANE WORKS

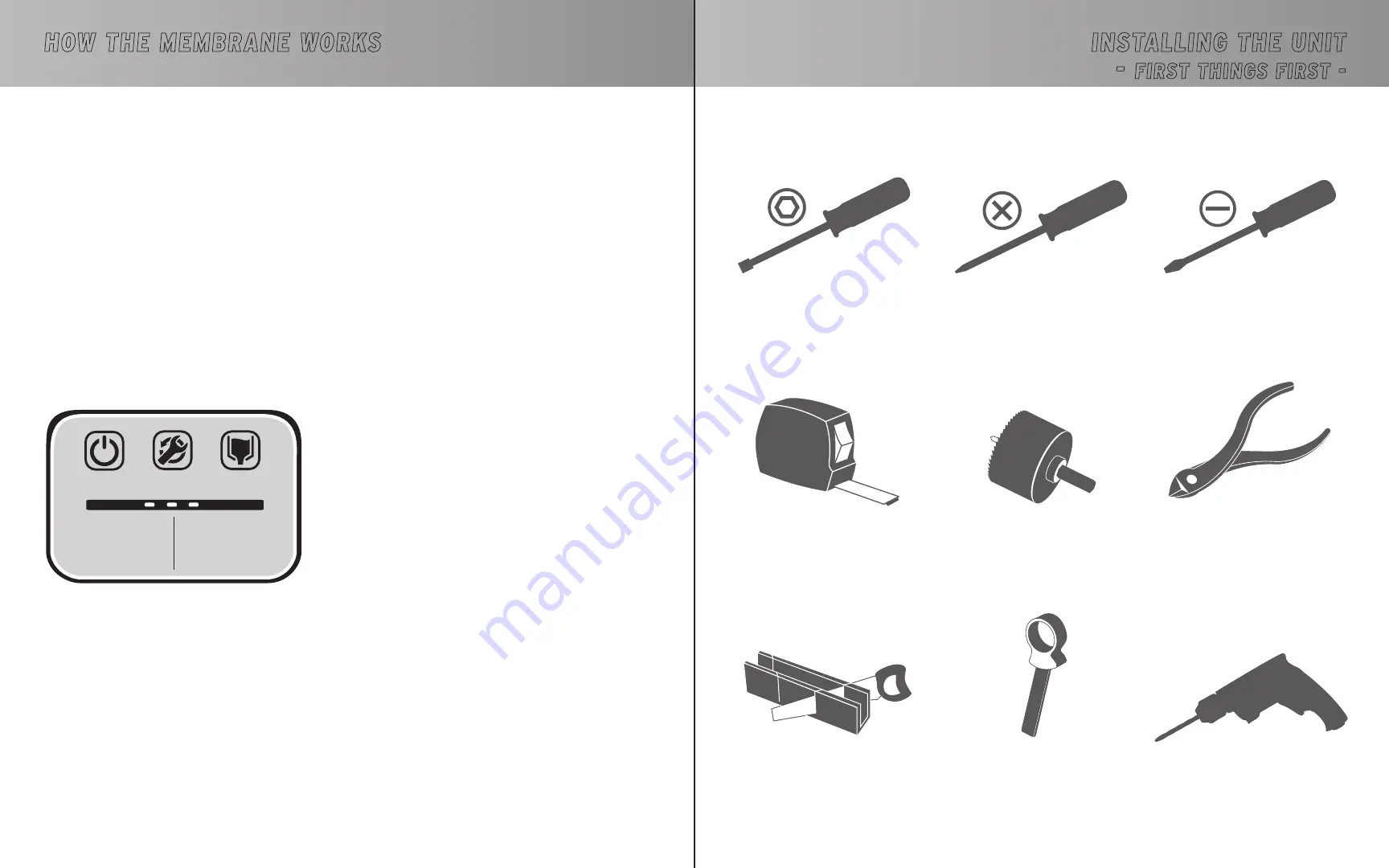

Cutting Pliers

Measuring Tape

Phillips Screwdriver

Hole Saw

2.25” (57 mm)

Drill

0.5” (12.5 mm) bit

Mitre-Box and Saw

PVC Pipe Cutter

2” (50 mm)

Regular Screwdriver

Socket Head Screwdriver

(for the clamps)

(supplied with the unit)

REQUIRED TOOLS

or

INSTALLING THE UNIT

-

FIRST THINGS FIRST -