47

46

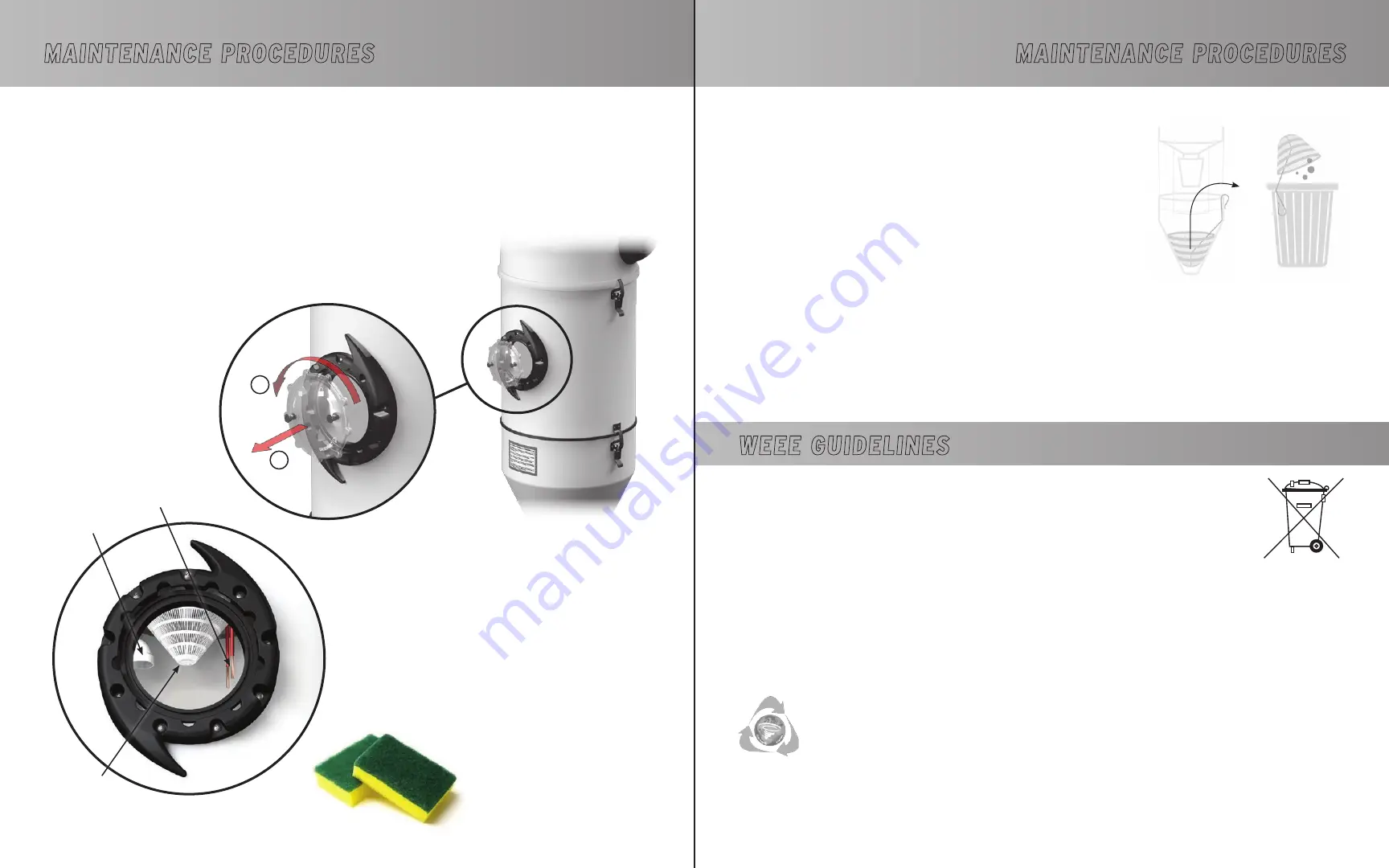

Figure F

1

2

This unit complies with the

WEEE (Waste Electrical and Electronic Equipment)

Guidelines,

which promote the recycling of this type of waste equipment and encourage

the development of products that are adapted to efficient waste reclamation at the end of

their life cycle.

The WEEE Guidelines stipulate that the original supplier should agree to reclaim any

obsolete equipment free of charge. We recommend that you advise your supplier that you

would like him to reclaim your unit when you order and replace it with a new one.

Do not discard the unit with your regular garbage. The symbol representing a garbage bin on wheels on the

unit’s label

(Figure F)

attests to this requirement. You must ensure that, at the end of its life cycle, your unit

is reclaimed, treated and recycled by an authorized firm.

For more information, contact your municipal waste management department.

The acquirer of the Automatik system is committed to respect the environmental

regulations of the liquid and solid waste disposal in the public water system.

WEEE GUIDELINES

MAINTENANCE PROCEDURES

DECANTER OPTION

• For residential applications: check and empty the decanter monthly

or after cleaning big amounts of fur, hair or any big objects.

• For commercial applications: check and empty daily.

MOTOR BRUSHES

Any mechanical system requires a minimum maintenance and your

system is no exception to the rule. We therefore recommend that you

inspect your motor brushes after 500 hours of use

to check how worn they are and replace them if need

be. On average, this inspection should occur once every 3 to 5 years for residential applications and once or

twice a year for commercial applications.

When the time comes, contact your retailer or distributor for this maintenance procedure.

Use a scouring sponge to

especially clean the protective

screen, the two electrodes

and, if needed, the funnel.

A blocked protective screen could reduce the unit’s

performance and dirty electrodes could not adequately

send a signal to the unit to pass on to the wastewater

evacuation cycle.

At the same time, it is recommended to

visually inspect

the water inlet pipe and the rubber hand to make sure

that no foreign object is obstructing the

water flow.

Protective

Screen

Water Inlet

Electrode

VISUAL INSPECTION

Your Automatik system is very user-friendly and

we recommend a visual inspection through the porthole

once a year or when needed.

If you wish to clean the inside of the unit, refer to the following section

“Regular Maintenance”.

REGULAR MAINTENANCE

Except for removing objects that could remain at the bottom of the

funnel (for the decanter configuration), the only maintenance required is

cleaning the inside of the unit.

To proceed, you just have to remove

the porthole glass as illustrated,

by pivoting it in an anti-clockwise

motion using the handles.

MAINTENANCE PROCEDURES