Summary of Contents for Autofog MLVH-10A

Page 1: ...AUTOFOG MLVH 10A Owners Manual...

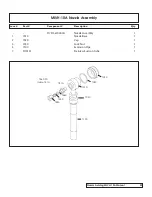

Page 12: ...Dramm Autofog MLVH 10A Manual 14 MLVH 10A Assembly Diagram...

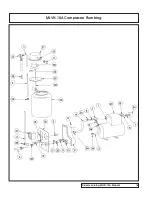

Page 14: ...Dramm Autofog MLVH 10A Manual 16 MLVH 10A Compressor Plumbing...

Page 15: ...MLVH 10A Compressor Plumbing Parts List 17 Dramm Autofog MLVH 10A Manual...

Page 16: ...MLVH 10A Compressor Diagram Dramm Autofog MLVH 10A Manual 18...

Page 17: ...MLVH 10A Compressor Parts List 19 Dramm Autofog MLVH 10A Manual...