15

10. OPERATING INSTRUCTIONS FOR 17684/17685.

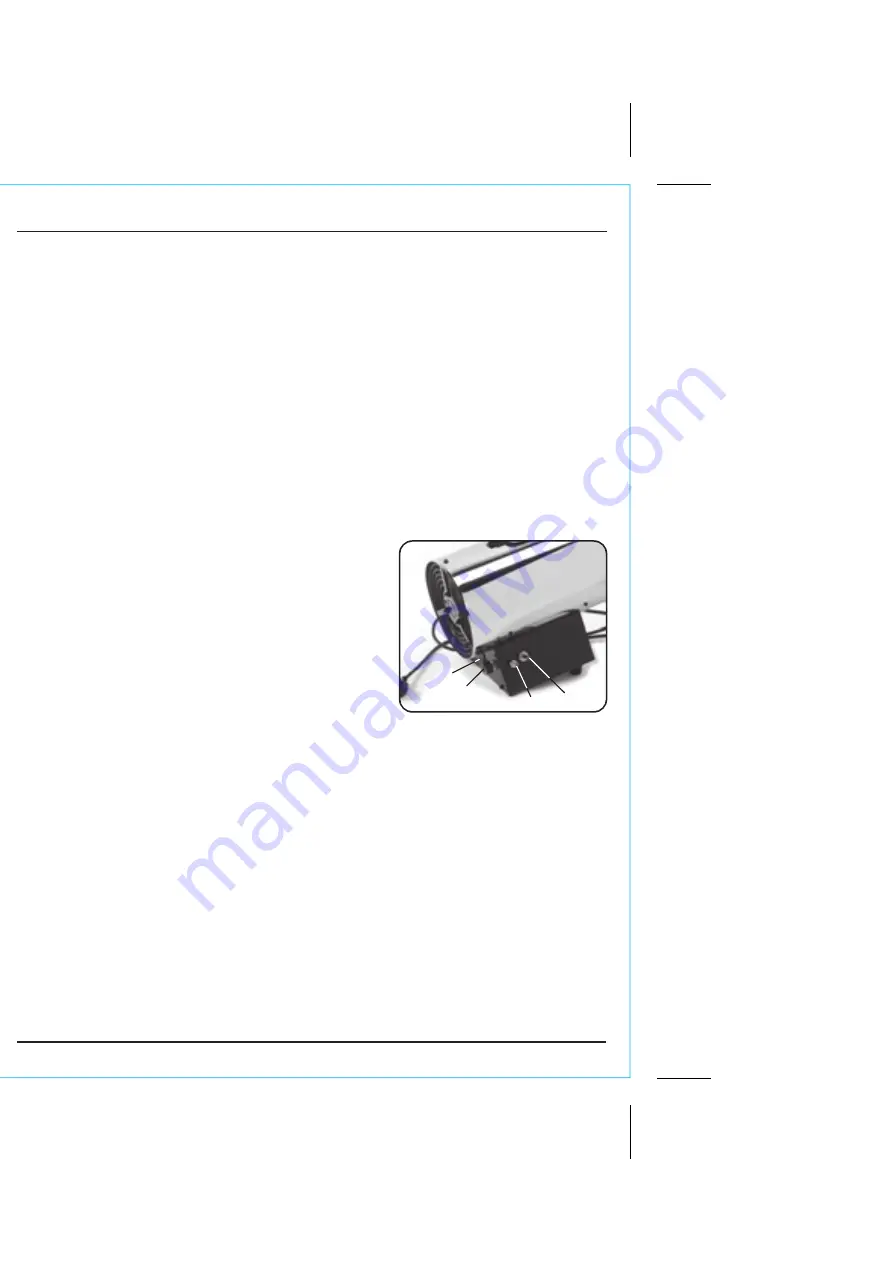

10.1 IGNITION SYSTEM - FIG. 6

Ignition is automatic with this heater as soon as the gas valve button is depressed, with a

continuous spark from the spark plug igniting the gas. As the thermocouple heats up, a low

voltage is fed to the Flame Failure valve, causing the valve to open, so that after a few

seconds, the gas valve button may be released and the flame is established.

10.2 SAFETY CONTROL SYSTEM

Should the flame extinguish for any reason, the thermocouple will quickly cool, causing the

Flame Failure valve to close, shutting off the gas supply. Similarly, should there be a power

failure, causing the fan motor to stop, the Safety Shut-Off valve solenoid will become

de-energised, and therefore shut off the gas supply.

Additionally, the machine is equipped with thermal overload protection, which will

intervene should the/unit overheat shutting off the electrical supply.

10.3 STARTING PROCEDURE

WARNING: BEFORE STARTING THE HEATER, YOU MUST ENSURE THAT THE MINIMUM

VENTILATION REQUIREMENTS ARE OBSERVED TO AVOID THE RISK OF CARBON MONOXIDE

POISONING.

1. Ensure there is sufficient gas and that it is correctly connected.

2. Open the supply valve on the gas cylinder, and fully

open the regulator valve adjacent to the gas inlet pipe.

3. Plug the heater in to a suitable power supply.

4. Set the flame intensity control valve

, to a low

setting.

5. Set the fan switch

to the ON (I) position. Confirm

the fan operates.

6. Hold in the gas valve button

, until the

thermocouple is energised and the heater ignites.

7. If the heater fails to ignite, there may be air in the hose

so keep the fuel valve open and wait for about 15

seconds. Walt 30 seconds for unburned fuel to exit the

heater. Repeat the step above.

8. When the burner remains lit set the heater at the required level by turning the flame

intensity control valve counter-clockwise. If the burner goes out. turn off the gas. Turn

the gas valve fully clockwise to its lowest position. Check the fuel supply. If adequate fuel

is available, re-start the heater from step 1.

Should the flame extinguish when the ignition button is released, wait for 1 minute, before

repeating the operation.

• Turning the flame intensity control valve anti-clockwise will increase the gas supply and

therefore the output clockwise to decrease. If ignition is difficult or irregular; ensure

the fan is operating and that the air inlet and outlet are completely clear. Also ensure

that the electrode gap is correct and that the electrode is clean (see Maintenance).

IMPORTANT:

Should the thermal overload protection feature operate and the spark plug is seen to be

operating, shut off the gas supply and allow the unit to cool for at least 10 minutes with the

fan running, before attempting to relight the burner.

Should the flame safety valve operate, the heater may be restarted once the cause of the

problem has been found and rectified.

FIG.6