- 2 -

- 3 -

1. INTRODUCTION

3. TECHNICAL

DESCRIPTION

1.1 SCOPE

This Lever Action Barrel Pump is a hand operated heavy duty pump designed to transfer oil

based fluids, heating oils, motor oils, diesel oil, kerosene, heavy & light oils

The pump comes complete with self adjusting telescopic suction tube, curved metal spout, and

1½" & 2" bung nut.

2. HEALTH AND SAFETY INFORMATION

2.1 GENERAL SAFETY INFORMATION

To ensure safe and efficient operation, it is essential to read and follow each of these warnings

and precautions.

1. Improper use or installation of this product can cause serious bodily injury or death.

2. Do NOT smoke near pump or use pump near an open flame. Fire could result.

3. When pumping flammable liquids, all equipment must be grounded to prevent the

accumulation of static electricity which may ignite vapours or gases.

4. The pump and containers should be connected using bonding clamps or clips and a

conductive wire no smaller than 12 gauge. A secure and positive metal-to-metal contact must

be made. The other end of the wire should be attached to a good ground, such as a steel

building column or water pipe.

Warning:

Leave handle in upright position when not in use.

4. ASSEMBLY

4.1 ASSEMBLY

1. Screw the suction tube assembly into the bung nut

. Tighten the connection securely to

eliminate any air leaks.

2. Screw the delivery spout nut

(part of the spout) onto the pump head. Tighten securely to

eliminate any possibility of leakage.

3. Extend the telescopic suction pipe

little longer than the height of the drum.

4. Screw the pump into the drum’s bung. Tighten the pump assembly securely by grasping the

pump body

and rotating.

5. Pull the plunger rod

of piston sub assembly up and attach the lever handle to the piston

rod using the pivot pin and retainer clip

.

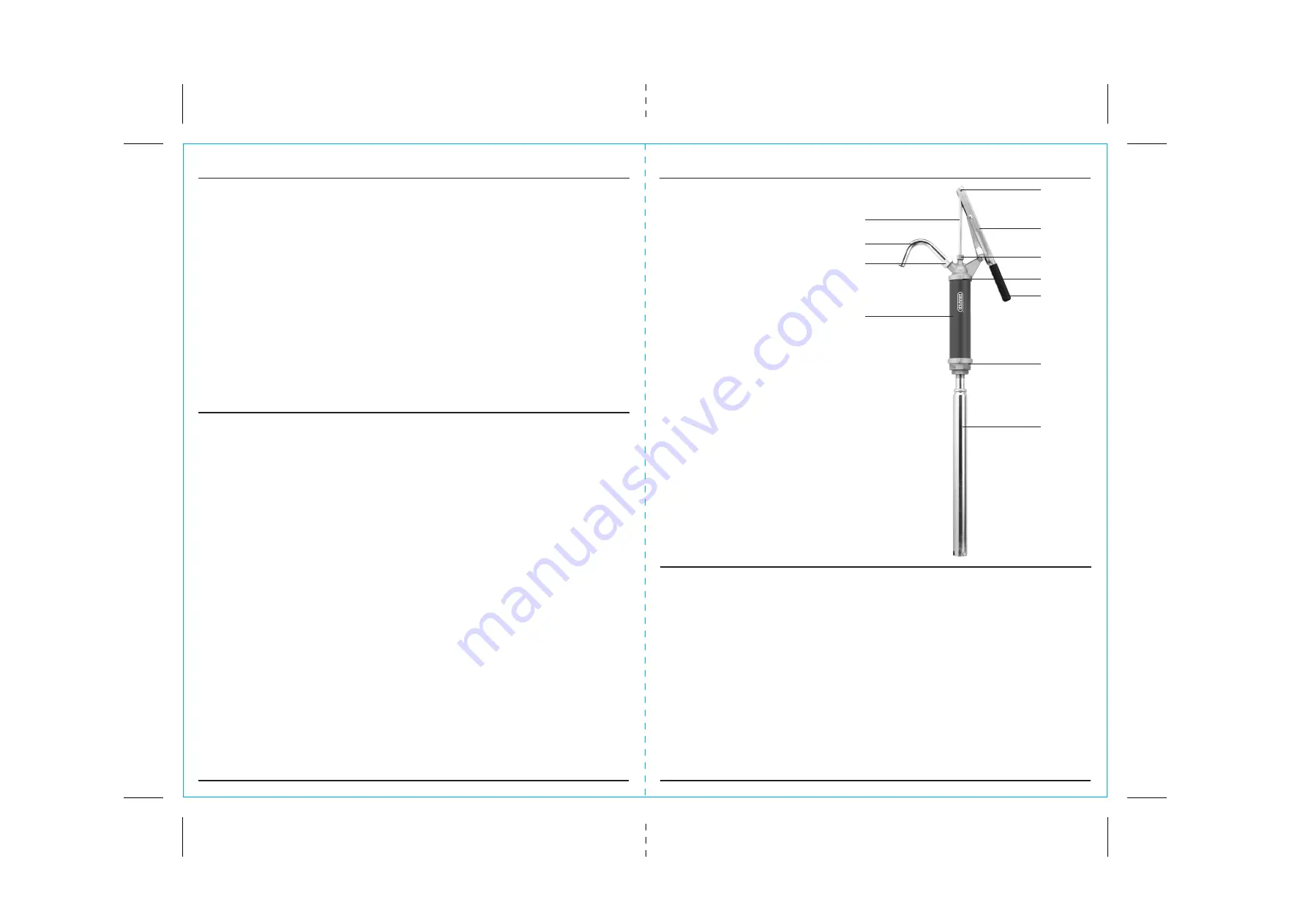

Pivot Pin & retainer clip.

Plunger

rod.

Lever

handle.

Delivery

spout

Compression

nut.

Spout

nut.

Pump

head.

Rubber

grip.

Pump

body.

Bung nut.

Suction tube assembly.

3.1 IDENTIFICATION

1.2 SPECIFICATION

Stock No’s. ............................................................................................................................... 47808

Part No’s. ................................................................................................................................. BP/G

Barrel size ..................................................................................................... 1½" & 2" bung adaptor

Delivery rate ....................................................................................... up to 300ml(10oz. per stroke)

Non return seal .......................................................................................................................... NBR

Wetted components................................................................ Steel, Aluminium, Zinc, Brass & NBR.

Recommended use:

.. Oil base fluids, heating oils, motor oils, diesel oil, kerosene, heavy & light oils.

Do not use: ...............

Water based fluids, solvents, acid, antifreeze or fluids that cause corrosion.