INSTRUCTIONS FOR

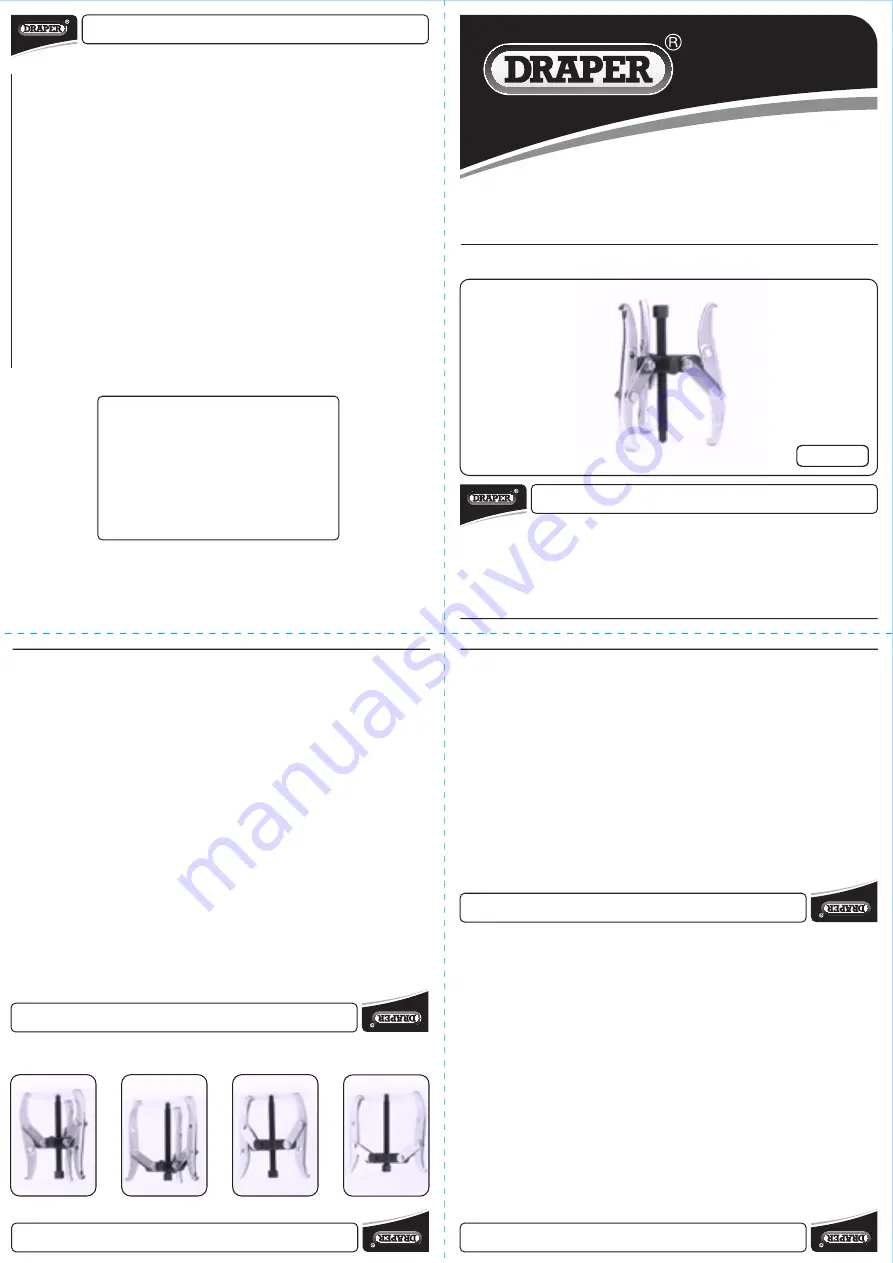

Twin/Triple

Reversible Puller

Stock No.56177 Part No.N136

This manual has been compiled by Draper Tools and is an integrated part of the product with which it is enclosed and

should be kept with it for future references.

This manual describes the purpose for which the product has been designed and contains all the necessary information

to ensure its correct and safe use. We recommend that this manual is read before any operation or, before performing

any kind of adjustment to the product and prior to any maintenance tasks. By following all the general safety instructions

contained in this manual, it will ensure both product and operator safety, together with longer life of the product itself.

All photographs and drawings in this manual are supplied by Draper Tools to help illustrate the operation of the product.

Whilst every effort has been made to ensure accuracy of information contained in this manual, the Draper Tools policy of

continuous improvement determines the right to make modifications without prior warning.

IMPORTANT:

PLEASE READ THESE INSTRUCTIONS CAREFULLY TO ENSURE THE SAFE AND

EFFECTIVE USE OF THIS PRODUCT.

CONTACTS

GENERAL INFORMATION

11/2004

-

DRAPER TOOLS LIMITED,

Hursley Road,

Chandler's Ford,

Eastleigh,

Hampshire.

SO53 1YF. U.K.

-

Helpline:

(023) 8049 4344.

-

Sales Desk:

(023) 8049 4333.

-

General Enquiries:

(023) 8026 6355.

-

Fax:

(023) 8026 0784

-

Internet:

www.draper.co.uk

-

E-mail:

sales@drapertools.com

YOUR DRAPER STOCKIST

©Published by Draper Tools Limited.

No part of this publication may be reproduced, stored in a retrieval system or

transmitted in any form or by any means, electronic, mechanical photocopying,

recording or otherwise without prior permission in writing from Draper Tools Ltd.

- 2 -

VERSATILITY

SAFETY

-

INFORMATION:

1.

Application of pressur

e on the forcing

screw incr

eases the grip of the

self-locking legs.

2.

By reversing the legs the amount of r

each

and spread can be varied to suit the job.

3.

The link nuts of this puller must not be

locked tight, as this will prevent the self-

locking action.

4.

Always clean and lubricate the forcing

screw befor

e and after use.

-

INSTRUCTIONS:

1.

Withdraw the forcing scr

ew to provide

sufficient reach.

2.

Ensure the puller is located at the centr

e

of the workpiece before applying any

pressur

e on the forcing scr

ew.

3.

Locate the reversible legs ar

ound the

workpiece. Hand tighten the

forcing scr

ew.

4.

Check that the puller is centrally located

and that the forcing scr

ew is lined up

with the axis of the shaft.

5.

Continue to apply pressur

e using the

correct size of spanner or socket on the

hexagon head of the forcing scr

ew.

6.

Hit the striking head of the forcing scr

ew

with a soft faced hammer and then re-

tighten with a spanner or socket.

7.

Continue this operation until the

workpiece is removed.

-

IMPORTANT

:

Trying to r

emove items by using the forcing

screw alone will str

ess the triple head and

screw thr

ead causing damage. For detailed

and concise instructions on the correct use

of this tool, refer to the vehicle

manufacturer’

s handbook.

-

SAFETY FIRST:

A. Ensur

e the tool is fitted squarely to

workpiece.

B.

Do not use excessive pressur

e.

C.

Avoid injur

y or damage due to sudden

release of pr

essure or r

esistance.

D.

Attempt to cover the puller and item

being pulled as a precaution against

flying debris.

E.

Take pr

ecautions against any sudden loss

of balance caused by the release of

pressur

e.

- 1 -

SPECIFICATION

The Draper Tools policy of continuous impr

ovement determines the right to change specification

without notice.

Stock No. ......................................................................................................................... 56177

Part No........................................................................................................................

...... N136

Maximum Reach............................................................................................................. 150m

m

Maximum Spread

............................................................................................................ 100mm

Two Leg

Short Leg

Reach............................................................................................................ 75mm

Spread

.......................................................................................................... 150mm

Long Leg

Reach.......................................................................................................... 120mm

Spread

.......................................................................................................... 150mm

Three Leg

Short Leg

Reach............................................................................................................ 75mm

Spread

.......................................................................................................... 150mm

Long Leg

Reach.......................................................................................................... 120mm

Spread

.......................................................................................................... 150mm

GUARANTEE

Draper tools have been carefully tested and inspected befor

e shipment and are guaranteed to be

free fr

om defective materials and workmanship.

Should the tool develop a fault, please return the complete tool to your near

est distributor or

contact Draper Tools Limited, Chandler's For

d, Eastleigh, Hampshire, SO53 1YF

. England.

Telephone: (023) 8026 6355.

If upon inspection it is found that the fault occurring is due to defective materials or

workmanship, repairs will be carried out fr

ee of charge. This guarantee period covering

parts/labour is 12 months from the date of pur

chase. The guarantee is extended to 24 months

for parts only. This guarantee does not apply to normal wear and tear , nor does it cover any

damage caused by misuse, careless or unsafe handling, alterations, accidents, or r

epairs

attempted or made by any personnel other than the authorised Draper warranty repair agent.

This guarantee applies in lieu of any other guarantee expressed or implied and variations of its

terms are not authorised.

Your Draper guarantee is not effective unless you can pr

oduce upon request a dated r

eceipt or

invoice to verify your proof of pur

chase within the guarantee period.

Please note that this guarantee is an additional benefit and does not affect your statutory rights.

Twin long leg.

Twin short leg.

Triple long leg.

Triple short leg.